Heavy Duty Carabiner Clip, Steel Review carabiner – Oemiu

Heavy Duty Carabiner Clip, Steel Review

The humble carabiner, often seen dangling from keychains or clipped onto backpacks, belies a world of engineering and rigorous testing. From securing climbers on sheer rock faces to connecting heavy loads in industrial settings, the heavy-duty steel carabiner clip stands as a testament to strength, reliability, and the critical importance of quality when lives and valuable equipment are on the line. But not all carabiners are created equal. Understanding the nuances of materials, gate types, load ratings, and intended applications is paramount when selecting the right one for the job. This article delves into the world of heavy-duty steel carabiners, exploring their construction, uses, and the factors that differentiate a reliable tool from a potential point of failure. Whether you’re a seasoned climber, a construction worker, or simply seeking a robust clip for everyday tasks, understanding the intricacies of these essential pieces of hardware can make all the difference.

Understanding the Backbone: Steel and Its Advantages

Steel, the workhorse of heavy-duty carabiner construction, offers a compelling combination of strength, durability, and affordability. Unlike aluminum, which prioritizes lightweight performance, steel carabiners excel in situations demanding maximum load-bearing capacity and resistance to wear and tear. The choice of steel grade significantly impacts a carabiner’s overall performance. High-strength alloy steels, often incorporating elements like chromium and molybdenum, provide exceptional tensile strength and resistance to deformation under heavy loads. This is crucial in applications where sudden impacts or sustained stress are anticipated. Consider the difference between a basic steel carabiner used for attaching a water bottle to a backpack and a high-grade alloy steel carabiner employed in a rigging system for lifting heavy machinery. The latter undergoes far more stringent testing and certification processes to ensure its ability to withstand immense forces. Furthermore, steel’s inherent resistance to abrasion makes it a superior choice in environments where the carabiner is likely to come into contact with rough surfaces, such as rocks, concrete, or metal edges. This durability translates to a longer lifespan and reduced risk of failure due to material degradation. While steel carabiners are generally heavier than their aluminum counterparts, the added weight is often a worthwhile trade-off for the increased strength and reliability they provide. Think about the consequences of a carabiner failure in a high-altitude rescue operation versus the minor inconvenience of carrying a slightly heavier piece of gear. The safety and security offered by a robust steel carabiner far outweigh the marginal increase in weight. Exploring options like a heavy duty spring clip carabiner ensures you get the exact type you need.

Corrosion Resistance: A Critical Consideration

One potential drawback of steel is its susceptibility to corrosion. However, manufacturers employ various techniques to mitigate this issue. Protective coatings, such as galvanization, powder coating, and zinc plating, create a barrier between the steel and the environment, preventing rust and extending the carabiner’s lifespan. The choice of coating depends on the specific application and the level of corrosion resistance required. For example, carabiners used in marine environments, where exposure to saltwater is constant, often feature specialized coatings that offer superior protection against corrosion. Regular inspection and maintenance are crucial for preserving the integrity of steel carabiners, particularly in harsh environments. Any signs of rust or coating damage should be addressed promptly to prevent further degradation. Simple measures, such as cleaning and lubricating the gate mechanism, can significantly extend the lifespan of a steel carabiner and ensure its continued safe operation. It’s important to note that even with protective coatings, steel carabiners are not entirely immune to corrosion. Prolonged exposure to extreme conditions can eventually lead to coating failure and subsequent rusting. Therefore, selecting a carabiner with an appropriate coating for the intended environment and adhering to regular maintenance practices are essential for maximizing its lifespan and reliability. The grade of stainless steel also plays a big role in how resilient these clips are to the elements. Higher grades, like 316 stainless steel, are often used in marine environments due to their superior corrosion resistance. Consider investing in a stainless steel carabiner clip heavy duty for environments where corrosion is a concern.

Gate Types and Locking Mechanisms: Choosing the Right Closure

The gate mechanism is arguably the most critical component of a carabiner, as it determines the ease of use, security, and overall reliability of the closure. Several gate types are available, each offering a unique combination of features and benefits. Spring-loaded gates are the most common type, providing quick and easy opening and closing. However, they are not inherently locking and can be susceptible to accidental opening if subjected to pressure or snagging. Screw-gate carabiners offer a simple and reliable locking mechanism. The gate is secured by a threaded sleeve that must be manually screwed down to prevent accidental opening. While slower to operate than spring-loaded gates, screw-gate carabiners provide a significant increase in security, making them suitable for applications where unintentional opening could have serious consequences. Twist-lock gates offer a compromise between speed and security. They feature a spring-loaded sleeve that automatically locks the gate when released. To open the gate, the sleeve must be twisted and pushed inward simultaneously, providing a high level of security while still allowing for relatively quick operation. Auto-locking gates are the most sophisticated type, offering the highest level of security and convenience. These gates automatically lock as soon as they close, eliminating the need for manual locking. They are ideal for applications where frequent clipping and unclipping are required and where security is paramount. The choice of gate type depends on the specific application and the level of security required. For example, a climber using a carabiner to belay a partner would likely opt for a locking gate, while someone using a carabiner to attach a water bottle to a backpack might be content with a simple spring-loaded gate. Furthermore, the locking mechanism itself can vary in complexity and reliability. Some screw-gate carabiners feature a simple, single-action screw, while others incorporate more sophisticated mechanisms that provide greater resistance to accidental loosening. Similarly, auto-locking gates can differ in their locking speed, ease of operation, and resistance to contamination by dirt or debris. Understanding these nuances is crucial for selecting a carabiner that meets the specific demands of the intended application. Looking into a large heavy duty locking carabiner will ensure that you can lift the items you need to.

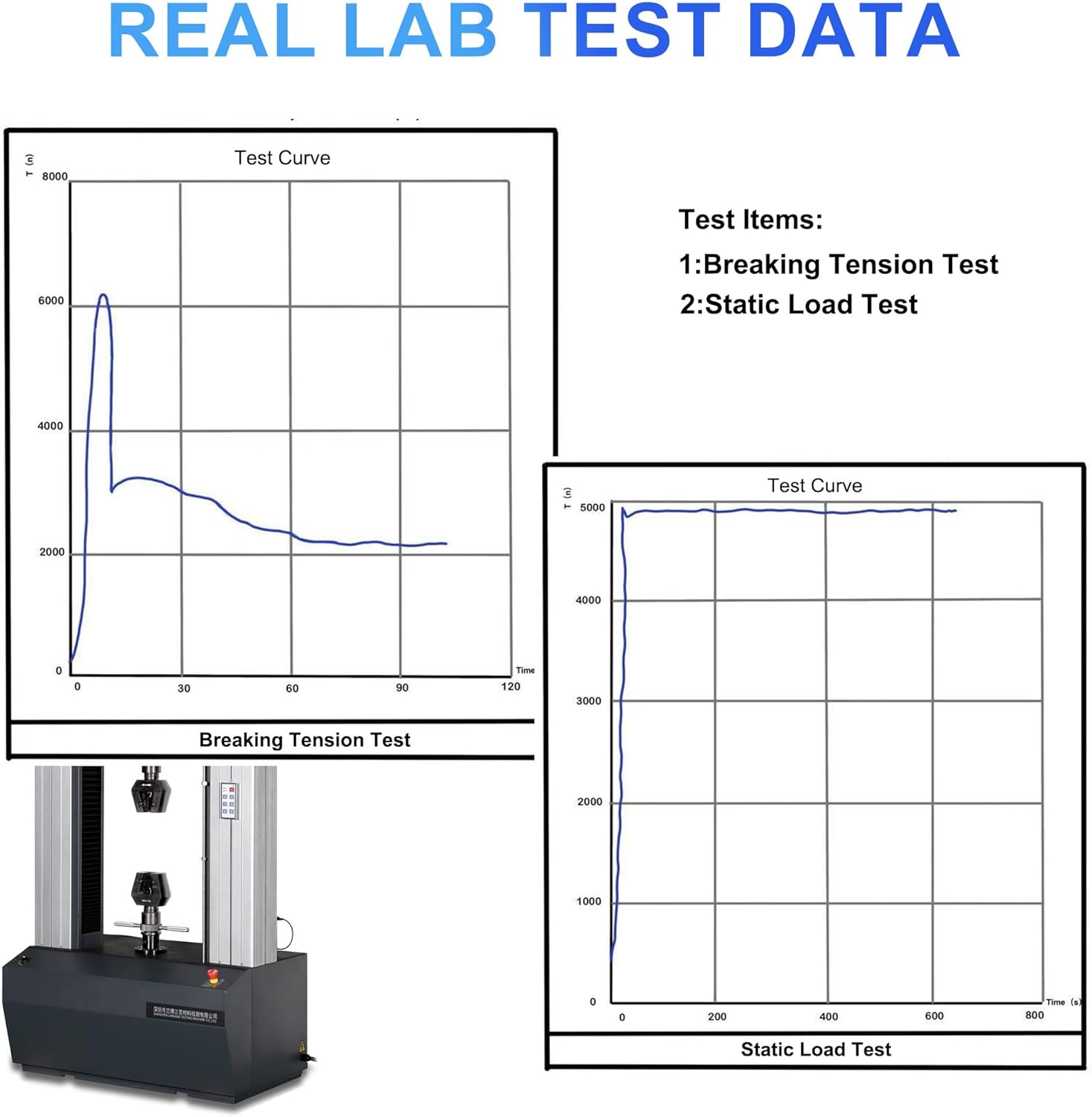

Gate Strength and Testing Standards

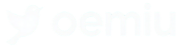

Regardless of the gate type, gate strength is a critical consideration. The gate is typically the weakest point of a carabiner, and its ability to withstand force is crucial for preventing failure. Reputable manufacturers adhere to rigorous testing standards to ensure that their carabiners meet or exceed industry requirements. These standards typically specify minimum breaking strengths for the gate in both the open and closed positions. The “gate open strength” is particularly important, as it reflects the carabiner’s ability to withstand force when the gate is not fully closed. This can occur when the carabiner is clipped onto an irregularly shaped object or when the gate is accidentally left partially open. The testing process typically involves applying a gradually increasing force to the carabiner until it fails. The force at which the carabiner fails is recorded and compared to the minimum breaking strength specified by the relevant standard. Carabiners that meet or exceed the minimum breaking strength are certified and labeled accordingly. It’s important to note that testing standards can vary depending on the intended application of the carabiner. For example, carabiners used in climbing are typically subject to more stringent testing standards than those used for general-purpose applications. Therefore, it’s essential to select a carabiner that is certified for the specific application for which it will be used. Look for certifications from reputable organizations such as the CE (Conformité Européenne) or the UIAA (International Climbing and Mountaineering Federation). These certifications indicate that the carabiner has been independently tested and verified to meet the requirements of the relevant standard. Furthermore, it’s crucial to inspect carabiners regularly for any signs of damage, such as cracks, bends, or corrosion. Any damaged carabiner should be immediately removed from service and replaced. Ensuring you get the correct strength is critical, and it helps to consider the most heavy duty carabiner to assess what’s right for you.

Load Ratings and Safety Factors: Understanding the Numbers

Load ratings are arguably the most important specifications to consider when selecting a heavy-duty steel carabiner. These ratings indicate the maximum force that the carabiner is designed to withstand before failure. Load ratings are typically expressed in kilonewtons (kN) or pounds-force (lbf). A kilonewton is a unit of force equal to approximately 224.8 pounds-force. Carabiners are typically rated for three different types of loads: major axis strength, minor axis strength, and gate open strength. The major axis is the longest dimension of the carabiner, and the major axis strength is the force that the carabiner can withstand when loaded along this axis. This is the strongest orientation for the carabiner, and the major axis strength is typically the highest load rating. The minor axis is the shortest dimension of the carabiner, and the minor axis strength is the force that the carabiner can withstand when loaded along this axis. This is a weaker orientation for the carabiner, and the minor axis strength is typically significantly lower than the major axis strength. The gate open strength, as discussed earlier, is the force that the carabiner can withstand when the gate is not fully closed. This is typically the weakest load rating and is particularly important to consider in situations where the gate may be accidentally left partially open. In addition to load ratings, it’s also important to understand the concept of safety factors. A safety factor is a multiplier that is applied to the load rating to account for uncertainties and variations in materials, manufacturing processes, and usage conditions. For example, a carabiner with a major axis strength of 25 kN and a safety factor of 4 is designed to withstand a maximum working load of 6.25 kN (25 kN / 4). The choice of safety factor depends on the specific application and the level of risk involved. Applications where failure could have serious consequences, such as climbing or rigging, typically require higher safety factors than applications where the risk of failure is lower. It’s crucial to never exceed the working load limit of a carabiner, as doing so can significantly increase the risk of failure. Furthermore, it’s important to consider the dynamic forces that may be applied to the carabiner during use. Dynamic forces are forces that are applied suddenly or repeatedly, such as those generated by a fall or impact. Dynamic forces can significantly increase the load on a carabiner, and it’s important to select a carabiner with a load rating that is sufficient to withstand these forces.

| Feature | Description | Importance |

|---|---|---|

| Material | Steel (alloy or stainless) | High for strength and durability |

| Gate Type | Screw-lock, twist-lock, auto-lock | Crucial for security and ease of use |

| Load Rating | Measured in kN or lbf (major axis, minor axis, gate open) | Essential for safe use |

| Safety Factor | Multiplier applied to load rating | Accounts for uncertainties |

| Corrosion Resistance | Galvanization, powder coating, stainless steel | Important for longevity in harsh environments |

| Certifications | CE, UIAA | Indicates compliance with safety standards |

Real-World Applications: From Climbing to Construction

The versatility of heavy-duty steel carabiners extends far beyond the realm of recreational climbing. In construction, these robust clips are essential components of rigging systems used to lift and secure heavy materials. From hoisting steel beams to suspending scaffolding, carabiners provide a reliable and secure connection point, ensuring the safety of workers and the stability of structures. The high load ratings and durability of steel make them ideal for withstanding the demanding conditions of construction sites. In industrial settings, heavy-duty carabiners play a critical role in various applications, including material handling, fall protection, and equipment anchoring. They are used to connect chains, ropes, and slings, providing a secure and reliable means of lifting and moving heavy objects. Furthermore, carabiners are an integral part of fall protection systems, providing a secure attachment point for safety harnesses and lanyards, protecting workers from falls from heights. Emergency services, such as fire departments and rescue teams, rely on heavy-duty steel carabiners for a wide range of tasks, including rappelling, rope rescue, and equipment securing. The strength and reliability of these clips are paramount in these situations, where lives may depend on their performance. From securing victims to anchoring rescue lines, carabiners are an essential tool for emergency responders. Even in everyday life, heavy-duty carabiners can be incredibly useful. They can be used to secure camping gear, attach tools to belts, or even hang heavy bags. The durability and strength of steel make them a reliable choice for a variety of tasks. Consider using a heavy duty caribeaner clip for shopping, hiking, or camping. The specific application of a heavy-duty steel carabiner dictates the features and specifications that are most important. For example, a carabiner used in climbing would prioritize strength, lightweight design, and ease of use, while a carabiner used in construction would prioritize maximum load-bearing capacity and durability. Therefore, it’s essential to carefully consider the intended application when selecting a carabiner to ensure that it meets the specific demands of the job.

Choosing the Right Carabiner for the Task at Hand

Selecting the right heavy-duty steel carabiner requires a careful assessment of the intended application, the expected loads, and the environmental conditions. Start by determining the maximum load that the carabiner will be subjected to. This should include both static loads (the weight of the object being supported) and dynamic loads (forces generated by movement or impact). Once the maximum load is known, select a carabiner with a load rating that exceeds this value by a significant margin, taking into account the safety factor. Next, consider the gate type. For applications where security is paramount, a locking gate (screw-gate, twist-lock, or auto-lock) is recommended. For applications where speed and ease of use are more important, a spring-loaded gate may be sufficient. However, it’s important to ensure that the spring-loaded gate is strong and reliable and that it is not susceptible to accidental opening. The material of the carabiner is also an important consideration. Steel is the most common material for heavy-duty carabiners, but the specific type of steel can vary. High-strength alloy steels offer superior strength and durability, while stainless steel offers excellent corrosion resistance. Choose a material that is appropriate for the environmental conditions in which the carabiner will be used. Finally, consider any specific features that may be required for the intended application. For example, some carabiners feature a swivel eye that allows the attached object to rotate freely, while others feature a large gate opening that makes it easier to clip onto thick ropes or webbing. By carefully considering these factors, you can select a heavy-duty steel carabiner that meets the specific demands of the job and provides a safe and reliable connection point.

Frequently Asked Questions

What is the difference between a steel carabiner and an aluminum carabiner?

The primary difference between steel and aluminum carabiners lies in their strength-to-weight ratio. Steel carabiners are significantly stronger than aluminum carabiners for a given size, but they are also heavier. This makes steel carabiners ideal for applications where maximum load-bearing capacity and durability are paramount, such as construction, rigging, and rescue operations. Aluminum carabiners, on the other hand, are lighter and more compact, making them suitable for applications where weight is a critical consideration, such as climbing and backpacking. However, aluminum carabiners are not as strong as steel carabiners and are more susceptible to wear and tear. The choice between steel and aluminum depends on the specific application and the trade-off between strength and weight. If strength is the primary concern, steel is the clear choice. If weight is the primary concern, aluminum may be a better option. However, it’s important to carefully consider the load ratings and safety factors of both types of carabiners to ensure that they are appropriate for the intended application. Remember, a carabiner failure can have serious consequences, so it’s always better to err on the side of caution.

How do I properly inspect a steel carabiner for damage?

Regular inspection is crucial for ensuring the continued safe operation of a steel carabiner. Before each use, visually inspect the carabiner for any signs of damage, such as cracks, bends, dents, or corrosion. Pay particular attention to the gate area, as this is the most vulnerable part of the carabiner. Check that the gate opens and closes smoothly and that the locking mechanism (if present) functions correctly. Also, inspect the carabiner for any signs of wear and tear, such as excessive abrasion or deformation. If you notice any of these issues, retire the carabiner immediately. Additionally, feel the carabiner for any sharp edges or rough spots that could indicate damage. If the carabiner has been subjected to a significant impact or load, even if there are no visible signs of damage, it should be retired from service. It’s important to keep detailed records of the carabiner’s usage and inspection history. This will help you track its condition over time and identify any potential problems before they become serious. Remember, a damaged carabiner is a potential point of failure, and it should never be used. When in doubt, retire the carabiner and replace it with a new one. The cost of a new carabiner is a small price to pay for your safety and the safety of others.

What is the lifespan of a steel carabiner?

The lifespan of a steel carabiner depends on several factors, including the frequency of use, the severity of the loads, the environmental conditions, and the level of maintenance. Under ideal conditions, a steel carabiner can last for many years. However, in harsh environments or under heavy use, the lifespan may be significantly shorter. Regular inspection is crucial for determining the remaining lifespan of a carabiner. If you notice any signs of damage, such as cracks, bends, dents, or corrosion, retire the carabiner immediately, regardless of its age. Even if the carabiner appears to be in good condition, it should be retired from service after a certain period of time. The manufacturer’s recommendations should be followed, but in general, a steel carabiner should be retired after 5-10 years of regular use, or after any single incident involving a significant load. Proper storage and maintenance can significantly extend the lifespan of a steel carabiner. Keep the carabiner clean and dry, and lubricate the gate mechanism regularly. Store the carabiner in a cool, dry place away from direct sunlight and corrosive chemicals. Remember, a carabiner’s lifespan is not indefinite, and it’s important to replace it before it becomes a safety hazard. Err on the side of caution and retire the carabiner if you have any doubts about its condition.

Can I use a steel carabiner for climbing?

Yes, steel carabiners can be used for climbing, but they are not as commonly used as aluminum carabiners. Steel carabiners are heavier than aluminum carabiners, which can be a significant disadvantage when climbing. However, steel carabiners are also stronger and more durable than aluminum carabiners, making them suitable for certain climbing applications, such as anchoring and rigging. When using steel carabiners for climbing, it’s important to select a carabiner that is specifically designed and certified for climbing use. Look for carabiners that meet the CE or UIAA standards for climbing equipment. Also, be sure to choose a carabiner with a load rating that is appropriate for the intended application. For example, a carabiner used for belaying should have a higher load rating than a carabiner used for clipping into a bolt. It is always crucial to check carabiner clip strength before use. Steel carabiners are also more resistant to wear and tear than aluminum carabiners, which can be an advantage when climbing in rough or abrasive environments. However, steel carabiners are also more susceptible to corrosion, so it’s important to keep them clean and dry. While they’re heavier, they can often be the right choice for the specific job or climate.

What are the different types of locking mechanisms available on steel carabiners?

Steel carabiners offer various locking mechanisms to prevent accidental gate opening, each with its own advantages and disadvantages. The most common types include screw-gate, twist-lock (also known as double-locking), and auto-locking carabiners. Screw-gate carabiners feature a threaded sleeve that manually screws up to block the gate opening. They are simple, reliable, and relatively inexpensive but require manual locking and unlocking, which can be slow. Twist-lock carabiners have a spring-loaded sleeve that requires twisting and pulling down before the gate can be opened. They offer a faster and more convenient locking mechanism than screw-gates, as the sleeve automatically locks upon release. Auto-locking carabiners are the most convenient and secure, automatically locking the gate as soon as it closes. They are ideal for applications where frequent clipping and unclipping are necessary. The choice of locking mechanism depends on the intended application. For situations where security is paramount, such as belaying or anchoring, auto-locking or twist-lock carabiners are recommended. For general-purpose use where speed is not critical, screw-gate carabiners may be sufficient. Remember, the purpose of a locking mechanism is to prevent accidental gate opening, so it’s crucial to choose a carabiner with a locking mechanism that is appropriate for the intended application.

How do I maintain a steel carabiner to ensure its longevity?

Proper maintenance is essential for extending the lifespan of a steel carabiner and ensuring its safe operation. After each use, clean the carabiner with a mild soap and water solution to remove any dirt, grime, or debris. Rinse thoroughly and allow the carabiner to air dry completely. Avoid using harsh chemicals or abrasive cleaners, as these can damage the carabiner’s finish or weaken the steel. Lubricate the gate mechanism regularly with a light oil or silicone lubricant. This will help keep the gate opening and closing smoothly and prevent corrosion. Avoid using grease or heavy lubricants, as these can attract dirt and debris. Inspect the carabiner regularly for any signs of damage, such as cracks, bends, dents, or corrosion. Pay particular attention to the gate area and the locking mechanism (if present). Store the carabiner in a cool, dry place away from direct sunlight and corrosive chemicals. Avoid storing the carabiner in a damp or humid environment, as this can accelerate corrosion. If the carabiner is exposed to saltwater, rinse it thoroughly with fresh water and allow it to air dry completely. By following these simple maintenance tips, you can significantly extend the lifespan of your steel carabiner and ensure its continued safe operation. Remember, a well-maintained carabiner is a reliable and valuable tool, but a neglected carabiner can be a safety hazard. Take the time to care for your carabiner, and it will serve you well for many years to come.

What should I do with a retired steel carabiner?

A retired steel carabiner should be disposed of in a responsible manner to prevent it from being used again by someone who may not be aware of its condition. The best option is to render the carabiner unusable by cutting it in half or otherwise deforming it. This will ensure that it cannot be used for its intended purpose. Once the carabiner has been rendered unusable, it can be recycled as scrap metal. Contact your local recycling center for information on how to recycle steel items. Avoid simply throwing the carabiner in the trash, as this could pose a hazard to others. If you are unsure how to dispose of a retired steel carabiner properly, contact the manufacturer or a local climbing or outdoor equipment retailer for advice. Some manufacturers may offer recycling programs for their products. It’s important to remember that a retired carabiner is no longer safe to use and should be disposed of in a way that prevents it from being used again. By following these steps, you can help protect others from the potential dangers of using a damaged or worn-out carabiner. Always prioritize safety and responsibility when disposing of retired equipment.

Price: $8.99 - $9.99

(as of Sep 13, 2025 06:43:21 UTC – Details)