Electric Hydraulic Scissor Lift Table Review scissor lift – Oemiu

Electric Hydraulic Scissor Lift Table Review: Finding the Right Lift for Your Needs

In today’s fast-paced industrial environment, efficiency and safety are paramount. One piece of equipment that can significantly contribute to both is the electric hydraulic scissor lift table. These versatile machines are found in a wide range of applications, from manufacturing and warehousing to retail and automotive repair. But with so many models and manufacturers available, choosing the right scissor lift can be a daunting task. This article delves into the world of electric hydraulic scissor lift tables, exploring their features, benefits, and key considerations to help you make an informed decision. We’ll also look at some common applications of these platforms, and what features make them excel in different scenarios. Ultimately, you should come away with the knowledge you need to select the best lifting solution for your unique operational requirements.

Understanding the Core Components and Functionality

At its heart, an electric hydraulic scissor lift table is a simple yet ingenious device. Its primary function is to raise and lower a platform using a scissor-like mechanism powered by a hydraulic system. The platform provides a stable surface for workers or materials, allowing them to reach elevated areas safely and efficiently. The “electric hydraulic” part of the name refers to the power source and the actuation method. An electric motor drives a hydraulic pump, which then forces hydraulic fluid into cylinders. These cylinders extend, pushing the scissor arms apart and raising the platform. The platform is lowered by releasing hydraulic fluid from the cylinders, allowing the scissors to collapse under the weight of the platform and its load.

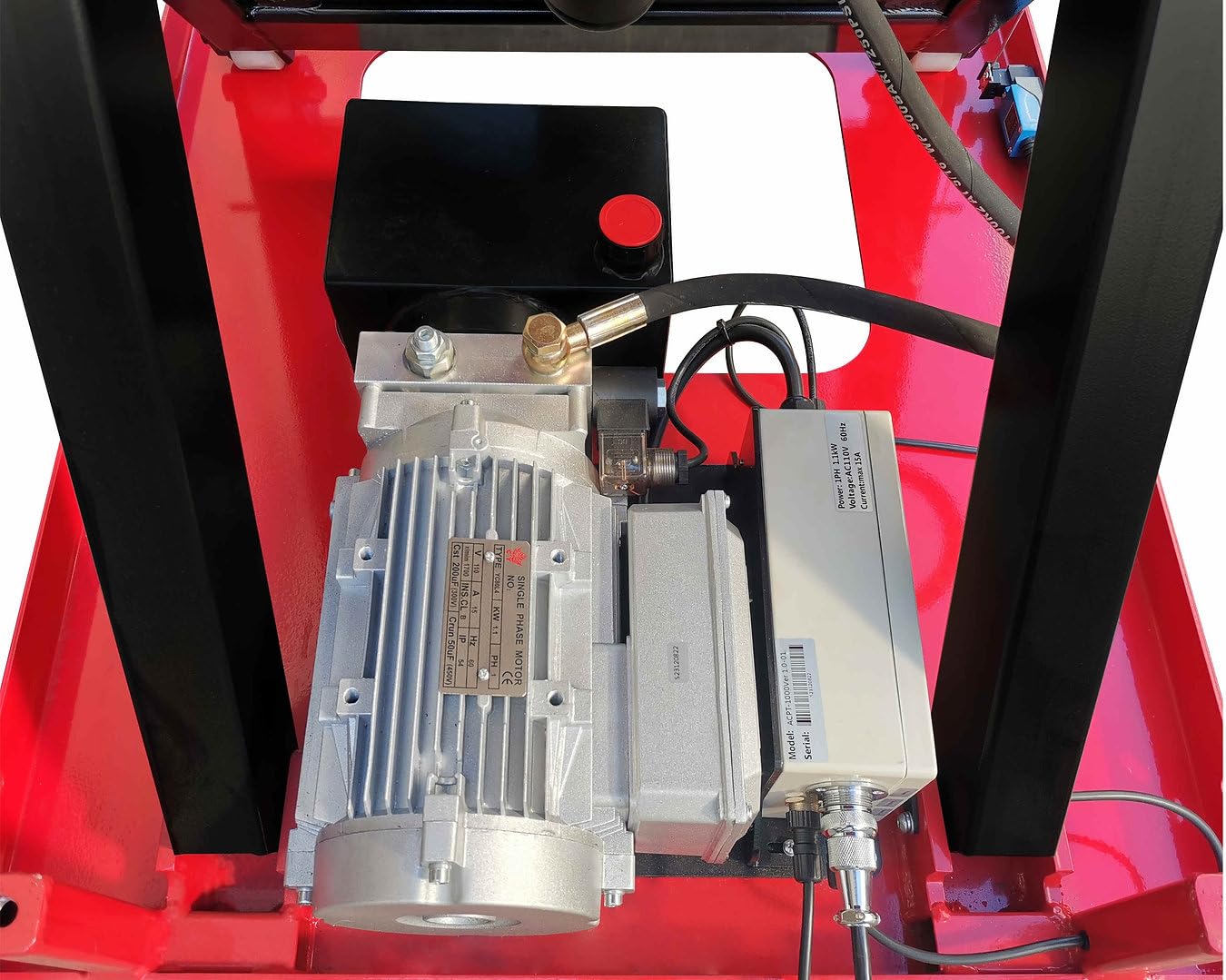

The core components of an electric hydraulic scissor lift table include: a sturdy base frame for stability; the scissor arms themselves, constructed from heavy-duty steel; hydraulic cylinders to provide the lifting force; an electric motor and hydraulic pump unit; a control panel for operation; and the platform, which is typically made of steel or aluminum. Safety features are crucial, and generally include overload protection, emergency stop buttons, and safety skirts to prevent objects from getting caught in the scissor mechanism. Some models also incorporate pressure relief valves to prevent damage in case of excessive load. Understanding these components is fundamental to appreciating the capabilities and limitations of different scissor lift designs. The quality of these components directly impacts the lift’s reliability, lifespan, and safety. For example, a lift with thicker steel scissor arms and a more powerful hydraulic pump will generally be able to handle heavier loads and withstand more demanding use.

The functionality of a scissor lift extends far beyond simply raising and lowering. It’s about creating a safe and ergonomic workspace. Consider a manufacturing plant where workers need to assemble components on a large machine. Without a scissor lift, they might have to climb ladders or awkwardly reach overhead, increasing the risk of accidents and reducing productivity. With a scissor lift, the workers can adjust the platform height to bring the work to a comfortable level, minimizing strain and maximizing efficiency. In a warehouse setting, a scissor lift can be used to safely load and unload pallets from trucks or stack them on shelves. The ability to precisely control the platform height allows for smooth and efficient material handling. Another crucial element of functionality is the control system. A well-designed control system allows for precise and intuitive operation, improving safety and efficiency. This often includes features like proportional control for smooth starts and stops, and diagnostic displays to quickly identify and resolve any issues. When evaluating a scissor lift, carefully consider the control system’s ease of use and responsiveness.

Finally, don’t underestimate the importance of mobility. While some electric hydraulic scissor lift tables are stationary, many are equipped with wheels or casters for easy movement around the workplace. This is especially valuable in environments where the lift needs to be used in multiple locations. Consider the type of flooring in your facility when selecting a mobile scissor lift. Hard, smooth floors will generally allow for easier movement than rough or uneven surfaces. Also, pay attention to the turning radius of the lift, as this will affect its maneuverability in tight spaces. Selecting the appropriate type of scissor lift table—whether a static or mobile unit, and ensuring it is tailored to your specific needs, will have a dramatic impact on workplace productivity and safety.

Comparing Different Types and Models of Electric Hydraulic Scissor Lift Tables

The market offers a diverse array of electric hydraulic scissor lift tables, each designed to cater to specific needs and applications. Broadly, these can be categorized based on their size, lifting capacity, platform dimensions, and features. Understanding these distinctions is crucial for selecting the right lift for your specific operational requirements. Some popular models include low-profile scissor lifts, which are ideal for applications where space is limited, and heavy-duty scissor lifts, which are designed to handle extremely heavy loads.

One key differentiator is the lifting capacity. Scissor lift tables range from models capable of lifting a few hundred pounds to those that can handle several tons. Consider the maximum weight of the materials or equipment that you’ll be lifting, and choose a lift with a capacity that exceeds that weight by a safe margin. It’s always better to err on the side of caution when it comes to lifting capacity. Another important factor is the platform size. The platform should be large enough to comfortably accommodate the workers or materials that will be on it. Consider the dimensions of the largest items you’ll be lifting, and choose a platform that provides adequate space. Some scissor lifts also offer extendable platforms, which can be useful for reaching awkward areas.

The lifting height is another critical specification. Determine the maximum height that you need to reach, and choose a lift that can provide that height. Keep in mind that the platform height is not the same as the working height. The working height is the height that a person can comfortably reach while standing on the platform. Ensure that the lift can provide the necessary working height for your application. In addition to these basic specifications, there are also a number of optional features that can enhance the functionality and safety of a scissor lift table. These include guardrails, toe boards, emergency stop buttons, and overload protection systems. Consider which features are essential for your application, and choose a lift that includes them. The overall footprint of the scissor lift is important in smaller workspaces. The folded dimensions of the lift should allow it to be easily stored when not in use, maximizing available floor space.

To illustrate the differences, consider this table comparing three popular electric hydraulic scissor lift tables:

| Model | Lifting Capacity | Platform Size | Max. Lifting Height | Features | Approx. Price |

|---|---|---|---|---|---|

| Model A (Low-Profile) | 1,000 lbs | 48″ x 30″ | 36″ | Foot pedal control, safety skirt | $2,500 |

| Model B (Standard) | 2,000 lbs | 60″ x 40″ | 48″ | Handheld pendant control, overload protection | $3,500 |

| Model C (Heavy-Duty) | 4,000 lbs | 72″ x 48″ | 60″ | Remote control, dual cylinders, safety railing | $6,000 |

This comparison highlights the trade-offs between different models. The low-profile model is ideal for space-constrained environments, while the heavy-duty model offers greater lifting capacity and height. Consider your specific needs and budget when making your selection. Another consideration is the power supply. Most electric hydraulic scissor lift tables operate on standard 110V or 220V power. However, some models may require a three-phase power supply. Ensure that your facility has the appropriate power supply before purchasing a scissor lift. Finally, consider the manufacturer’s reputation and warranty. Choose a reputable manufacturer with a proven track record of quality and reliability. A good warranty will protect you against defects and ensure that you can get the lift repaired or replaced if necessary. A mobile elevating work platform like the electric hydraulic scissor lift table can provide tremendous safety and efficiency in the workspace, but only if chosen with careful consideration to your specific use cases.

Safety Considerations and Best Practices for Operating Scissor Lift Tables

Safety is paramount when operating any type of machinery, and electric hydraulic scissor lift tables are no exception. A well-maintained and properly operated scissor lift can significantly improve workplace safety, but negligence or improper use can lead to serious accidents. Understanding the potential hazards and following established safety protocols are crucial for ensuring a safe working environment. Before operating a scissor lift, always conduct a thorough inspection to ensure that all components are in good working order. Check the hydraulic hoses for leaks, the scissor arms for damage, and the platform for any cracks or dents. Verify that the safety devices, such as the emergency stop buttons and overload protection system, are functioning correctly. Never operate a scissor lift that is damaged or in need of repair. A pre-operation checklist ensures nothing gets overlooked.

Proper training is essential for all operators. Only authorized and trained personnel should be allowed to operate a scissor lift. Training should cover the lift’s operation, safety features, and potential hazards. Operators should be familiar with the manufacturer’s instructions and any applicable regulations. A robust training program not only minimizes the risk of accidents but also ensures that operators can efficiently and effectively use the equipment. One of the most common causes of scissor lift accidents is overloading. Always adhere to the manufacturer’s specified weight capacity. Distribute the load evenly on the platform to prevent instability. Never exceed the weight limit, as this can cause the lift to tip over or collapse. Uneven loading can put excessive stress on certain components, leading to premature failure. The scissor lift working platform is not designed to be a general free for all.

Maintaining a safe working environment around the scissor lift is also crucial. Keep the area clear of obstacles and debris. Ensure that there is adequate lighting. Warn nearby workers of the lift’s operation and take steps to prevent collisions. Use barricades or warning tape to cordon off the work area, if necessary. Communication is key in crowded workplaces. Operators should use hand signals or verbal communication to coordinate with other workers. Proper maintenance is essential for keeping a scissor lift in safe operating condition. Follow the manufacturer’s recommended maintenance schedule. Regularly lubricate moving parts, check the hydraulic fluid levels, and inspect the electrical wiring. Promptly address any repairs or maintenance issues. A proactive maintenance program can prevent breakdowns and extend the life of the lift. The proper maintenance schedule will ensure the mobile elevating work platform remains within safe operating guidelines.

Finally, always be aware of your surroundings. Watch out for overhead obstructions, such as power lines or pipes. Be mindful of the terrain, and avoid operating the lift on uneven or unstable surfaces. Never operate a scissor lift in windy conditions, as this can increase the risk of tipping over. By following these safety guidelines and best practices, you can significantly reduce the risk of accidents and ensure a safe working environment for yourself and others. Remember that safety is everyone’s responsibility, and that a little bit of caution can go a long way. Regular safety audits are important. They can help identify potential hazards and ensure that safety protocols are being followed. Conducting regular audits reinforces the importance of safety and encourages workers to be more vigilant. Prioritize safety above all else, and use electric hydraulic scissor lift tables responsibly. Remember to always use fall protection equipment, such as harnesses and lanyards, when working at heights.

Real-World Applications and Case Studies

Electric hydraulic scissor lift tables find application across a remarkably diverse range of industries and settings. Their versatility and ability to enhance both safety and efficiency have made them indispensable tools in many workplaces. From the bustling environment of a manufacturing plant to the meticulous work of aircraft maintenance, these lifts play a critical role in facilitating various tasks. Exploring some real-world applications and case studies provides valuable insights into their practical benefits and how they can be leveraged to improve operational effectiveness. In manufacturing, scissor lifts are often used to assemble products, transport materials, and perform maintenance on machinery. Consider a large automotive manufacturing plant where workers need to install heavy components on a vehicle chassis. Using a scissor lift, the workers can easily raise and lower the components to the correct height, reducing the risk of strain injuries and improving assembly speed.

In warehousing and logistics, scissor lifts are essential for loading and unloading trucks, stocking shelves, and picking orders. A large distribution center might use several scissor lifts to efficiently handle pallets of goods. The lifts allow workers to safely raise and lower pallets to the appropriate height, minimizing the risk of damage and improving throughput. Retail environments also benefit from the use of scissor lifts. In a large department store, scissor lifts can be used to restock shelves, install displays, and perform maintenance on lighting fixtures. The lifts allow workers to reach high shelves safely and efficiently, without the need for ladders or scaffolding. In the aviation industry, scissor lifts are crucial for aircraft maintenance and repair. Mechanics use scissor lifts to access hard-to-reach areas of the aircraft, such as the wings, tail, and engine. The lifts provide a stable and safe platform for performing inspections, repairs, and replacements. The scissor lift working platform is invaluable in this setting, where precision and safety are paramount.

Consider a case study of a small machine shop that implemented an electric hydraulic scissor lift table to improve its operations. The shop specialized in fabricating custom metal parts, and the workers were constantly struggling to lift and position heavy materials. This led to frequent strain injuries and reduced productivity. After investing in a scissor lift, the shop saw a significant improvement in both safety and efficiency. Workers were able to lift and position materials with ease, reducing the risk of injuries and increasing their output. The lift also allowed the shop to take on larger and more complex projects, expanding its business opportunities. In another case study, a large food processing plant used scissor lifts to automate its packaging line. The lifts were integrated into the conveyor system, automatically raising and lowering boxes of product. This eliminated the need for manual lifting, reducing the risk of injuries and increasing the speed of the packaging process. The electric hydraulic scissor lift table improved both worker safety and reduced repetitive motion injuries.

These real-world examples demonstrate the versatility and benefits of electric hydraulic scissor lift tables. By providing a safe and efficient way to lift and position materials, these lifts can significantly improve productivity, reduce injuries, and expand business opportunities. The specific application of the lift will depend on the industry and the specific needs of the workplace, but the underlying principle remains the same: to provide a safe and efficient way to work at heights. When evaluating potential applications for a scissor lift, consider the tasks that currently require manual lifting, awkward positioning, or working at heights. Assess the potential for a scissor lift to improve safety, efficiency, and productivity. Talk to your workers and get their input on how a scissor lift could make their jobs easier and safer. By carefully considering your specific needs and the potential benefits, you can make an informed decision about whether or not a scissor lift is the right solution for your workplace. The electric work platform can greatly improve workflow across many different sectors.

FAQ

What are the key benefits of using an electric hydraulic scissor lift table?

Electric hydraulic scissor lift tables offer a multitude of benefits across various industries and applications. Perhaps the most significant advantage is the enhancement of workplace safety. By providing a stable and adjustable platform, these lifts minimize the need for ladders, scaffolding, and other potentially hazardous methods of working at heights. This reduces the risk of falls and other accidents, creating a safer environment for workers. Improved ergonomics is another major benefit. Scissor lifts allow workers to position materials and equipment at a comfortable and accessible height, reducing strain and fatigue. This can lead to fewer repetitive motion injuries and increased worker satisfaction. Increased productivity is another key advantage. By providing a more efficient way to lift and position materials, scissor lifts can significantly speed up work processes. This can translate into increased output and reduced labor costs. Ultimately, the electric hydraulic scissor lift table proves to be a powerful and versatile tool.

How do I choose the right size and capacity scissor lift for my needs?

Selecting the appropriate size and capacity scissor lift is crucial for ensuring safe and efficient operation. Start by carefully assessing the maximum weight of the materials or equipment you’ll be lifting. Choose a lift with a capacity that exceeds this weight by a safe margin, typically at least 20%. Next, consider the dimensions of the largest items you’ll be lifting and choose a platform size that provides adequate space. The platform should be large enough to comfortably accommodate the workers or materials that will be on it. Determine the maximum height that you need to reach and choose a lift that can provide that height. Remember to factor in the working height, which is the height that a person can comfortably reach while standing on the platform. Finally, consider the available space in your workplace and choose a lift with a footprint that fits within that space. Don’t forget to account for maneuvering room and storage space when the lift is not in use.

What are the common safety features to look for in a scissor lift table?

When evaluating electric hydraulic scissor lift tables, safety should be your top priority. Look for models that incorporate a range of safety features to protect workers and prevent accidents. Some essential safety features include: Overload protection, which prevents the lift from operating if the weight capacity is exceeded; Emergency stop buttons, which immediately halt the lift’s operation in case of an emergency; Safety skirts, which prevent objects from getting caught in the scissor mechanism; Guardrails, which provide a barrier to prevent falls from the platform; and Toe boards, which prevent tools or materials from rolling off the platform. Pressure relief valves are also essential for preventing damage to the hydraulic system in case of excessive load. Additionally, look for models with non-slip platform surfaces and clear warning labels.

How often should I perform maintenance on my scissor lift table?

Regular maintenance is essential for keeping your electric hydraulic scissor lift table in safe and reliable operating condition. The frequency of maintenance will depend on the lift’s usage and the manufacturer’s recommendations. However, as a general guideline, you should perform a daily pre-operation inspection to check for any obvious damage or defects. This inspection should include checking the hydraulic hoses for leaks, the scissor arms for damage, and the platform for any cracks or dents. You should also perform a more thorough inspection and maintenance every three to six months, depending on usage. This should include lubricating moving parts, checking the hydraulic fluid levels, inspecting the electrical wiring, and testing the safety devices. Follow the manufacturer’s recommended maintenance schedule for specific instructions and intervals. Keep detailed records of all maintenance performed, including dates, descriptions of work performed, and any parts replaced.

What are some potential hazards associated with operating scissor lifts?

Despite their many benefits, electric hydraulic scissor lift tables also pose potential hazards if not operated properly. Some common hazards include: Overloading, which can cause the lift to tip over or collapse; Falls from the platform, which can result in serious injuries; Crushing injuries, which can occur if a worker gets caught in the scissor mechanism; Electrocution, which can occur if the lift comes into contact with overhead power lines; Tip-overs, which can occur if the lift is operated on uneven or unstable surfaces; and Collisions, which can occur if the lift is not properly controlled or if the area is not clear of obstacles. By being aware of these potential hazards and following established safety protocols, you can significantly reduce the risk of accidents.

Are there any specific regulations or standards I need to be aware of?

Yes, there are several regulations and standards that govern the operation of electric hydraulic scissor lift tables. In the United States, the Occupational Safety and Health Administration (OSHA) sets forth safety regulations for the use of scissor lifts. These regulations cover topics such as operator training, inspection requirements, and safe operating procedures. In addition to OSHA regulations, there are also industry standards developed by organizations such as the American National Standards Institute (ANSI). These standards provide guidance on the design, construction, and operation of scissor lifts. It’s essential to be familiar with all applicable regulations and standards before operating a scissor lift. Failure to comply with these regulations can result in fines, penalties, and, more importantly, accidents. Consult with your local OSHA office or a qualified safety professional for more information.

What is the typical lifespan of an electric hydraulic scissor lift table?

The typical lifespan of an electric hydraulic scissor lift table can vary depending on several factors, including the quality of the lift, the frequency of use, the maintenance schedule, and the operating environment. However, with proper care and maintenance, a well-built scissor lift can last for 10 to 20 years or even longer. Factors that can shorten the lifespan of a scissor lift include: Heavy usage, which can put excessive wear and tear on the components; Neglecting maintenance, which can lead to premature failures; Operating in harsh environments, such as dusty or corrosive conditions; and Exceeding the weight capacity, which can damage the hydraulic system. To maximize the lifespan of your scissor lift, choose a high-quality model from a reputable manufacturer, follow the recommended maintenance schedule, operate the lift within its specified limits, and protect it from harsh environmental conditions. Regular inspections and timely repairs can also help extend its lifespan.

Price: $258.99 - $2,650.00

(as of Sep 06, 2025 05:03:45 UTC – Details)