Bonbo 10Pcs Flanged Ball Bearings ID Review wheel bearing – Oemiu

Bonbo 10Pcs Flanged Ball Bearings ID Review: A Deep Dive into Versatile Rotation

In the world of mechanics, engineering, and DIY projects, the unassuming ball bearing plays a critical role. These small, often overlooked components are the unsung heroes of smooth, efficient rotation. From the intricate workings of a precision instrument to the robust demands of an automotive wheel, ball bearings enable movement with minimal friction and maximum reliability. The Bonbo 10Pcs Flanged Ball Bearings ID set promises a versatile solution for a wide array of applications. This review delves into the specifics of this bearing set, exploring its features, potential uses, and overall value proposition. We will examine why these flanged ball bearings might be the right choice for your next project, and where they might fall short compared to alternative solutions.

Understanding Flanged Ball Bearings: A Detailed Exploration

Flanged ball bearings, as the name suggests, incorporate a flange on the outer ring. This flange serves several crucial purposes. Firstly, it simplifies mounting. The flange provides a surface that can be easily secured to a housing or support structure, eliminating the need for complex machining or specialized mounting hardware. Secondly, it provides axial positioning. The flange acts as a stop, preventing the bearing from moving along the shaft or within its housing. This is particularly important in applications where precise positioning is critical. Think of a robotic arm where accurate movement is paramount; flanged ball bearings contribute to the overall precision. The flange can also offer additional support and rigidity to the bearing, enhancing its load-bearing capacity in certain configurations. This makes flanged bearings a good choice for supporting axial loads in addition to radial loads. This inherent stability often makes them a preferred choice when assembling complex mechanisms or systems requiring consistent and reliable performance. The Bonbo set, boasting an inner diameter (ID) suitable for a variety of shaft sizes, offers flexibility in design and implementation. The specific dimensions are vital; ensure they align with your intended application before purchase. Ignoring this detail can result in wasted time, effort and potential damage to the bearing or associated components.

The construction of a flanged ball bearing typically involves several key components: the inner ring, the outer ring (with the flange), the balls, and the cage (also known as a retainer). The inner and outer rings provide the raceways for the balls to roll upon. The balls themselves are precisely manufactured to ensure uniform size and hardness, contributing to smooth and consistent rotation. The cage keeps the balls evenly spaced, preventing them from clumping together and reducing friction. The material selection for each of these components is crucial. High-quality bearings typically use hardened steel for the rings and balls, and a durable plastic or metal for the cage. The Bonbo bearings should specify their material composition, which is a critical factor in determining their longevity and suitability for specific operating conditions. For example, if the bearings are intended for use in a corrosive environment, stainless steel construction would be highly desirable. Similarly, high-speed applications require bearings with close tolerances and a well-designed cage to prevent excessive vibration and wear. Selecting the proper wheel bearing for a specific need necessitates understanding the environmental and operational conditions it will endure.

Applications of Flanged Ball Bearings

The versatility of flanged ball bearings makes them suitable for a vast array of applications. In the realm of robotics, they are frequently used in joints and actuators, providing smooth and precise rotational movement. Their ability to handle both radial and axial loads makes them ideal for supporting rotating shafts and ensuring accurate positioning. In 3D printers, flanged bearings are commonly found in linear motion systems, guiding the movement of the print head along the X, Y, and Z axes. The flange allows for easy mounting and ensures that the bearings remain securely in place during the printing process. Within the automotive sector, these bearings might be employed in steering mechanisms or smaller motorized components within the vehicle. They are also present in various types of machinery, from conveyor systems to power tools. In hobbyist applications, flanged bearings are used in remote-controlled vehicles, model trains, and other small-scale mechanical devices. The ease of mounting and the smooth rotational performance make them a popular choice for DIY projects. Considering their widespread application in so many different sectors highlights the importance of choosing the right bearing for the job. For instance, using a Bonbo bearing in a small RC car project is vastly different than the stresses and loads that a heavy-duty automotive vehicle wheel bearing endures.

| Application | Benefits of Using Flanged Ball Bearings |

|---|---|

| Robotics | Precise movement, support for radial and axial loads, easy integration into joints and actuators. |

| 3D Printers | Smooth linear motion, secure mounting, accurate positioning of the print head. |

| Automotive | Support in steering mechanisms, smooth rotation, durability. |

| Machinery | Reliable operation, reduced friction, extended lifespan of rotating components. |

| Hobbyist Projects | Easy mounting, smooth rotation, affordability. |

Bonbo 10Pcs Flanged Ball Bearings ID: Features and Benefits

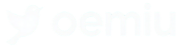

The Bonbo 10Pcs Flanged Ball Bearings ID set offers a combination of features aimed at providing a reliable and cost-effective solution for various rotational applications. Key features often include: a standardized inner diameter (ID) for compatibility with common shaft sizes, a flanged outer ring for simplified mounting, precision-ground raceways for smooth rotation, and durable materials for extended lifespan. The benefits derived from these features are numerous. The ease of mounting saves time and effort during installation, reducing the need for specialized tools or machining. The smooth rotational performance minimizes friction and wear, improving the efficiency and longevity of the application. The durable materials ensure that the bearings can withstand the rigors of continuous use, reducing the need for frequent replacements. The set of 10 bearings provides a cost-effective solution for projects requiring multiple bearings, or for having spares on hand. It is imperative to confirm the precise ID measurement, as even slight variations can hinder performance. Moreover, ensuring proper lubrication is critical for longevity. Consider the operating environment and load requirements when selecting a lubricant.

When evaluating the Bonbo bearing set, consider these points. The bearing’s dimensions are crucial. Confirm that the inner diameter, outer diameter, and flange dimensions are compatible with your application. The material composition determines the bearing’s resistance to wear, corrosion, and temperature extremes. The load capacity specifies the maximum weight or force that the bearing can withstand. Check the bearing’s speed rating, which indicates the maximum rotational speed at which the bearing can operate safely. Bearing clearance refers to the amount of internal play or looseness within the bearing. Different applications require different levels of clearance. Consider the method used for shielding and sealing. Shielded bearings offer protection against dust and debris, while sealed bearings provide greater protection against liquids and contaminants. Finally, the manufacturing tolerances affect the bearing’s precision and rotational smoothness. Tighter tolerances generally result in better performance. Bearings used for precision machinery need to have tight tolerances to maintain accuracy.

Pros and Cons of the Bonbo 10Pcs Flanged Ball Bearings ID Set

Like any product, the Bonbo 10Pcs Flanged Ball Bearings ID set has its strengths and weaknesses. Understanding these pros and cons can help you make an informed decision about whether this bearing set is right for your needs. Some of the pros might include:

* Cost-effectiveness: The set of 10 bearings offers excellent value for money.

* Easy Mounting: The flanged design simplifies installation, reducing the need for specialized tools.

* Versatile Application: Suitable for a wide range of projects, from robotics to 3D printing.

* Smooth Rotation: Precision-ground raceways ensure smooth and efficient operation.

* Availability: Readily available online and from various retailers.

However, there are some potential cons to consider:

* Material Quality: Depending on the specific model, the materials used may not be suitable for heavy-duty applications. It’s crucial to research the specific materials used in the construction.

* Tolerance: Manufacturing tolerances may not be as tight as those found in higher-end bearings.

* Lubrication: The bearings may require additional lubrication before use. Check if they are pre-lubricated or if you need to apply your own.

* Origin: The bearings might be sourced from less established manufacturers, which could impact quality control.

* Packaging: The packaging might not be robust enough to protect the bearings during shipping. Inspect the bearings carefully upon arrival to ensure that they have not been damaged.

| Pros | Cons |

|---|---|

| Cost-effective | Material quality may vary |

| Easy Mounting | Tolerances may not be as tight as higher-end bearings |

| Versatile Application | May require additional lubrication |

| Smooth Rotation | Origin of manufacture may impact quality control |

| Readily Available | Packaging may not be robust |

Alternatives and Considerations for Wheel Bearings

While the Bonbo 10Pcs Flanged Ball Bearings ID set offers a compelling solution for many applications, it’s essential to consider alternatives and other factors that might influence your choice. Different types of bearings, such as deep groove ball bearings, thrust bearings, or roller bearings, may be more suitable for specific applications. For instance, deep groove ball bearings are designed to handle high radial loads, while thrust bearings are better suited for axial loads. Roller bearings, such as cylindrical or tapered roller bearings, can handle even higher loads than ball bearings. The operating environment is another crucial consideration. If the bearings will be exposed to extreme temperatures, corrosive substances, or high levels of vibration, you may need to choose bearings made from specialized materials or with enhanced sealing. High-speed applications require bearings with close tolerances and a well-balanced design to minimize vibration and noise. Automotive applications demand extremely durable bearings that can withstand the constant stress and impact. Automotive wheel bearings are a good example of how critical a bearing can be to the operation of a larger system. Using the proper type of wheel bearing can greatly enhance the performance of a vehicle and ensure the safety of the passengers.

Price is always a factor in any purchasing decision. While the Bonbo bearings offer excellent value, it’s important to balance cost with quality and performance. Cheaper bearings may not last as long or perform as well as more expensive options. In the long run, it may be more cost-effective to invest in higher-quality bearings that require less frequent replacement. Consider the overall lifespan of your application and the potential consequences of bearing failure. If the bearings are used in a critical application where failure could result in significant downtime or safety hazards, it’s worth spending more to ensure reliability. Always factor in maintenance requirements when selecting bearings. Some bearings require frequent lubrication or other maintenance to ensure optimal performance. Choose bearings that are easy to maintain and that fit your maintenance capabilities. Even the best wheel bearing will eventually need replacement, so factoring this into maintenance is important. Finally, consider the reputation and reliability of the manufacturer. Established manufacturers with a proven track record of quality and customer service are generally a safer bet than unknown brands. It’s also advisable to read online reviews and seek recommendations from other users before making a purchase.

Ensuring Longevity and Optimal Performance

To maximize the lifespan and performance of your Bonbo 10Pcs Flanged Ball Bearings ID set, it’s essential to follow proper installation and maintenance procedures. Start by ensuring that the shaft and housing are clean and free from debris. Use appropriate tools and techniques to install the bearings without damaging them. Apply a high-quality lubricant to the bearings before use. Choose a lubricant that is compatible with the bearing materials and suitable for the operating conditions. Avoid over-lubricating the bearings, as this can attract dirt and debris. Regularly inspect the bearings for signs of wear, corrosion, or damage. Replace worn or damaged bearings promptly to prevent further damage to the application. Pay attention to any unusual noises or vibrations coming from the bearings. These can be indicators of underlying problems. Protect the bearings from contaminants such as dust, dirt, and moisture. Use shielded or sealed bearings in environments where contaminants are present. Store the bearings in a clean, dry place when not in use. Proper storage will prevent corrosion and extend the lifespan of the bearings. A wheel bearing specifically designed to reduce road noise can make a significant difference for vehicles. Finally, don’t overload the bearings beyond their rated capacity. Exceeding the load capacity can lead to premature failure.

Frequently Asked Questions (FAQ)

What is the difference between a shielded and a sealed ball bearing?

Shielded ball bearings have metal shields that are press-fit into the outer ring of the bearing. These shields provide a non-contact seal, protecting the bearing from larger particles of dust and debris. They are suitable for applications where contamination is moderate. Sealed ball bearings, on the other hand, have rubber or plastic seals that make contact with both the inner and outer rings of the bearing. These seals provide a more effective barrier against contaminants, including dust, dirt, and moisture. They are ideal for applications where contamination is severe or where the bearing is exposed to liquids. Sealed bearings typically offer better protection but may generate more friction due to the contact between the seals and the bearing rings. This additional friction may be a factor in high-speed applications, making shielded bearings a more optimal choice when contamination is low.

How do I choose the right size ball bearing for my application?

Selecting the correct size of ball bearing hinges on several factors related to your application. First, determine the shaft diameter that the bearing will be supporting. The inner diameter (ID) of the bearing must match the shaft diameter. Next, consider the space constraints of your application. The outer diameter (OD) of the bearing must fit within the available space. Finally, determine the load capacity required for your application. The bearing must be able to withstand the radial and axial loads that it will be subjected to. Consult bearing catalogs or online resources to find bearings that meet your requirements for ID, OD, and load capacity. If you are replacing an existing bearing, simply measure the ID, OD, and width of the old bearing and select a replacement with the same dimensions. Using the correct dimensions is critical for proper function and longevity. Consulting a mechanical engineer or experienced technician might be useful for critical or heavy-duty applications.

What is the difference between radial and axial load?

Radial load is a force that acts perpendicular to the axis of rotation of the bearing. Imagine a weight hanging from a shaft that is supported by bearings; the weight exerts a radial load on the bearings. Axial load, also known as thrust load, is a force that acts parallel to the axis of rotation. Imagine pushing on the end of a shaft that is supported by bearings; the force you are applying is an axial load. Different types of bearings are designed to handle different types of loads. Deep groove ball bearings can handle both radial and axial loads, but they are best suited for radial loads. Thrust bearings are specifically designed to handle axial loads. Roller bearings can handle higher radial loads than ball bearings. Understanding the types of loads that your bearings will be subjected to is essential for selecting the correct type of bearing. Many mechanical components may exert both radial and axial forces on a wheel bearing at the same time, underscoring the importance of selecting one that can withstand both.

How often should I lubricate my ball bearings?

The frequency of lubrication for ball bearings depends on several factors, including the type of bearing, the operating conditions, and the type of lubricant used. In general, bearings that are exposed to high speeds, high temperatures, or heavy loads will require more frequent lubrication. Sealed bearings, which have a built-in lubricant, typically require less frequent lubrication than shielded bearings. As a general rule of thumb, lubricate ball bearings every 6 to 12 months for light-duty applications. For heavy-duty applications, lubricate them every 1 to 3 months. Use a high-quality lubricant that is compatible with the bearing materials and suitable for the operating conditions. Consult the bearing manufacturer’s recommendations for specific lubrication intervals and lubricant types. Over-lubrication can be as detrimental as under-lubrication, so follow the recommendations carefully. Consistent lubrication, using the correct lubricant, will extend the lifespan of your bearings and ensure optimal performance.

What causes ball bearing failure?

Ball bearing failure can result from various factors, often stemming from improper usage, environmental conditions, or material degradation. Common causes include fatigue failure, which occurs due to repeated stress cycles exceeding the material’s endurance limit, leading to cracks and eventual breakdown. Contamination from dirt, debris, or moisture can cause abrasive wear, reducing the bearing’s smooth operation and lifespan. Improper lubrication can lead to increased friction, heat buildup, and accelerated wear. Overloading, exceeding the bearing’s load capacity, can cause deformation and premature failure. Corrosion due to exposure to corrosive substances or high humidity can weaken the bearing material. Finally, improper installation, such as using excessive force or misalignment, can damage the bearing and reduce its performance. Addressing these causes through proper maintenance, lubrication, and careful installation can significantly extend the lifespan of ball bearings.

Can I replace a ball bearing myself, or should I hire a professional?

Whether you can replace a ball bearing yourself depends on several factors, including your mechanical aptitude, the complexity of the application, and the tools required. For simple applications, such as replacing a bearing in a skateboard wheel or a small electric motor, you may be able to do it yourself with basic tools and some online guidance. However, for more complex applications, such as replacing a wheel bearing in a car or a bearing in a high-precision machine, it is generally advisable to hire a professional. These applications often require specialized tools and expertise to ensure that the bearing is installed correctly and safely. Improper installation can lead to premature bearing failure and potentially dangerous situations. If you are unsure about your ability to replace a ball bearing, it is always best to err on the side of caution and seek professional assistance. Keep in mind that a properly installed and maintained wheel bearing can greatly enhance driving safety.

How can I tell if a ball bearing is going bad?

Identifying a failing ball bearing early can prevent more significant damage and costly repairs. Several telltale signs can indicate a deteriorating bearing. Increased noise is often the first indicator. Listen for unusual grinding, squealing, or rumbling sounds coming from the bearing assembly. Excessive vibration can also signify a problem. Feel for any unusual vibrations or shaking when the equipment or machinery is running. Increased heat is another sign. A failing bearing generates more friction, leading to increased heat. Carefully touch the bearing housing to check for excessive warmth. Play or looseness in the bearing can indicate wear. Try to move the shaft or component that the bearing is supporting. Excessive play or looseness suggests that the bearing is worn. Finally, visible signs of damage, such as cracks, corrosion, or discoloration, can be a clear indication of a failing bearing. Any of these signs warrant a thorough inspection and possible replacement of the ball bearing. Identifying a bad wheel bearing quickly can avoid safety issues with driving, such as wheel collapse.

Price: $59.99 - $14.99

(as of Sep 08, 2025 08:03:42 UTC – Details)