Hydro-Gear Genuine Commercial Transaxle Review transaxle fluid – Oemiu

Hydro-Gear Genuine Commercial Transaxle Fluid Review: Optimizing Performance and Longevity

For professionals and serious homeowners relying on the robust performance of Hydro-Gear commercial transaxles in their mowers, zero-turn vehicles, and other heavy-duty equipment, choosing the right transaxle fluid is paramount. The fluid isn’t merely lubrication; it’s the lifeblood of the system, responsible for efficient power transfer, heat dissipation, and protection against wear and tear. Using the correct fluid can significantly extend the lifespan of your transaxle, reduce maintenance costs, and ensure consistent, reliable performance. This article delves into the specifics of Hydro-Gear’s genuine commercial transaxle fluid, exploring its composition, benefits, proper usage, and why opting for the manufacturer’s recommended fluid is often the most prudent choice. We will also touch upon understanding specific transaxle fluid requirements for different applications, comparing it with aftermarket alternatives, and ultimately making an informed decision about the best fluid for your equipment.

Understanding the Vital Role of Transaxle Fluid

The transaxle in a commercial mower or vehicle is a complex piece of machinery, combining the functions of a transmission and an axle into a single unit. This compact design maximizes efficiency and power delivery, but it also places significant demands on the lubricating fluid. Within the transaxle, gears mesh together under immense pressure, generating heat and friction. The fluid’s primary function is to reduce this friction, preventing excessive wear and ensuring smooth operation. However, its role extends far beyond simple lubrication. High-quality transaxle fluid, like Hydro-Gear’s genuine offering, also acts as a hydraulic fluid, transmitting power within the system. It needs to maintain its viscosity under a wide range of temperatures, from scorching summer heat to freezing winter conditions. Furthermore, the fluid must protect internal components from corrosion, contamination, and the formation of sludge or varnish. This is especially crucial in commercial applications where equipment is often subjected to harsh conditions and prolonged use. Choosing the correct “hydrostatic transmission oil” is therefore a critical decision. Using an inferior or incompatible fluid can lead to premature failure of the transaxle, resulting in costly repairs and downtime. Genuine fluids are specifically formulated to meet the exacting requirements of the transaxle, ensuring optimal performance and longevity.

Consider the scenario of a landscaping company relying on a fleet of zero-turn mowers during the peak season. Each mower operates for hours every day, often in dusty and demanding environments. If the transaxles are filled with a generic or inappropriate fluid, the increased friction and heat can lead to accelerated wear on the gears, bearings, and other internal components. This can manifest as reduced power, jerky movements, or even complete transaxle failure. The resulting downtime can disrupt the company’s schedule, leading to missed appointments and lost revenue. On the other hand, using Hydro-Gear’s genuine commercial transaxle fluid can help prevent these issues. The fluid’s superior lubricating properties, heat resistance, and corrosion protection ensure that the transaxles operate smoothly and efficiently, even under heavy use. This translates to improved productivity, reduced maintenance costs, and a longer lifespan for the equipment.

Furthermore, the specific formulation of Hydro-Gear’s fluid is designed to work in harmony with the seals and other materials used in their transaxles. Using a fluid that is not compatible with these materials can lead to swelling, shrinking, or degradation of the seals, resulting in leaks and loss of fluid. This can further exacerbate wear and damage to the transaxle. Therefore, while aftermarket fluids may seem like a cheaper alternative, they may not offer the same level of protection and compatibility as the genuine product. In the long run, the cost of using an inferior fluid can far outweigh the initial savings.

Dissecting Hydro-Gear’s Genuine Commercial Transaxle Fluid: Composition and Key Features

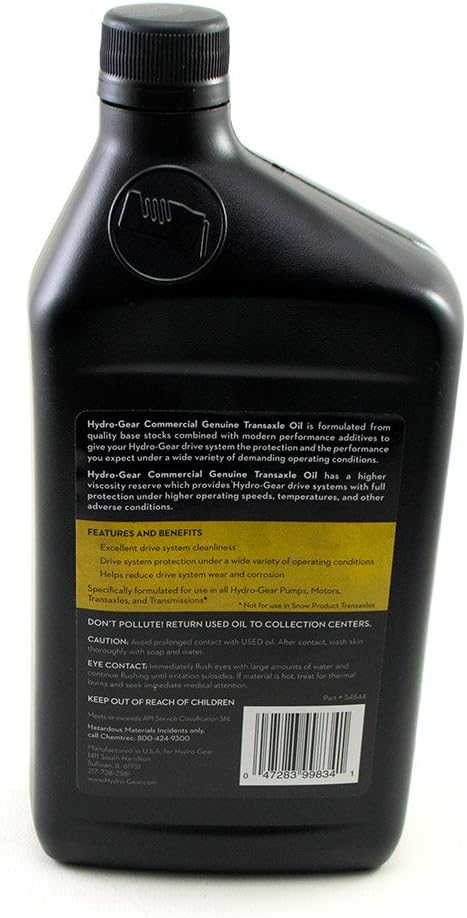

Hydro-Gear’s genuine commercial transaxle fluid isn’t just a generic oil; it’s a carefully engineered blend of base oils and additives designed specifically for the demanding requirements of their transaxles. The base oil provides the primary lubricating properties, while the additives enhance its performance in various ways. These additives can include detergents to keep internal components clean, dispersants to suspend contaminants and prevent them from clumping together, anti-wear agents to reduce friction and wear, corrosion inhibitors to protect against rust and corrosion, and viscosity index improvers to maintain the fluid’s viscosity over a wide range of temperatures. The exact composition of the fluid is proprietary, but Hydro-Gear emphasizes the use of high-quality synthetic or semi-synthetic base oils and a balanced additive package to ensure optimal performance and longevity.

Here are some of the key features that distinguish Hydro-Gear’s genuine commercial transaxle fluid:

- Superior Lubricity: Reduces friction and wear, extending the lifespan of transaxle components.

- Excellent Thermal Stability: Maintains viscosity and performance at high temperatures, preventing overheating and breakdown.

- Enhanced Corrosion Protection: Protects internal components from rust and corrosion, especially in humid or wet environments.

- Improved Shear Stability: Resists breakdown under high shear stress, ensuring consistent performance over time.

- Optimized Hydraulic Performance: Provides efficient power transfer within the transaxle.

- Seal Compatibility: Designed to be compatible with the seals and other materials used in Hydro-Gear transaxles, preventing leaks.

- Foam Resistance: Prevents the formation of foam, which can reduce lubrication and hydraulic performance.

The use of synthetic or semi-synthetic base oils in Hydro-Gear’s fluid offers several advantages over conventional mineral oils. Synthetic oils have a more uniform molecular structure, which results in better thermal stability, improved lubricity, and longer service life. They are also less prone to oxidation and breakdown at high temperatures. This means that synthetic or semi-synthetic fluids can provide superior protection and performance, especially in demanding commercial applications where equipment is subjected to heavy use and high temperatures. Furthermore, the carefully selected additive package in Hydro-Gear’s fluid is designed to work in synergy with the base oil, providing a balanced and comprehensive level of protection. This includes anti-wear additives that form a protective layer on metal surfaces, reducing friction and wear. Corrosion inhibitors that neutralize acids and prevent rust formation, and viscosity index improvers that maintain the fluid’s viscosity over a wide range of temperatures. This “hydrostatic fluid for mowers” can make a noticeable difference.

| Feature | Hydro-Gear Genuine Fluid | Typical Aftermarket Fluid |

|---|---|---|

| Base Oil | Synthetic or Semi-Synthetic | Mineral or Synthetic Blend |

| Thermal Stability | Excellent | Good to Average |

| Corrosion Protection | Excellent | Good |

| Shear Stability | Excellent | Good to Average |

| Seal Compatibility | Optimized for Hydro-Gear Seals | General Purpose |

| Additive Package | Specifically Formulated | Generic |

The Benefits of Using Genuine Hydro-Gear Transaxle Fluid

Choosing genuine Hydro-Gear transaxle fluid for your commercial equipment provides a multitude of benefits that extend beyond just lubrication. These benefits directly contribute to improved performance, reduced maintenance costs, and a longer lifespan for your transaxles. The advantages are particularly noticeable in demanding commercial applications where equipment is subjected to heavy use and harsh conditions. One of the most significant benefits is the enhanced protection against wear and tear. The superior lubricity and anti-wear additives in Hydro-Gear’s fluid reduce friction between moving parts, preventing premature wear on gears, bearings, and other critical components. This translates to a longer lifespan for the transaxle and reduced repair costs.

Another key benefit is the improved thermal stability of the fluid. Hydro-Gear’s fluid is designed to maintain its viscosity and performance at high temperatures, preventing overheating and breakdown. This is crucial in commercial applications where equipment is often operated for extended periods in hot weather. Overheating can lead to accelerated wear and damage to the transaxle, potentially resulting in costly repairs or even complete failure. By using a fluid with excellent thermal stability, you can help prevent overheating and ensure that your transaxles operate reliably, even under demanding conditions. Furthermore, the enhanced corrosion protection provided by Hydro-Gear’s fluid helps to prevent rust and corrosion on internal components. This is particularly important in humid or wet environments where corrosion can be a significant problem. Corrosion can weaken metal parts and lead to premature failure. By protecting against corrosion, Hydro-Gear’s fluid helps to extend the lifespan of your transaxles and reduce the need for costly repairs. “Best hydrostatic oil” searches often lead users to consider only viscosity; protection is equally important.

Here’s a summary of the key benefits:

- Extended Transaxle Lifespan: Reduced wear and tear on internal components leads to a longer lifespan for the transaxle.

- Improved Performance: Smooth and efficient power transfer results in better overall performance of the equipment.

- Reduced Maintenance Costs: Fewer repairs and less downtime translate to lower maintenance costs.

- Enhanced Reliability: Consistent and reliable performance, even under demanding conditions.

- Protection Against Overheating: Excellent thermal stability prevents overheating and breakdown of the fluid.

- Corrosion Protection: Prevents rust and corrosion on internal components, extending their lifespan.

- Optimal Seal Compatibility: Ensures that the fluid is compatible with the seals used in Hydro-Gear transaxles, preventing leaks.

Consider a golf course that relies on a fleet of turf mowers to maintain its greens and fairways. These mowers operate for hours every day, often in hot and humid conditions. If the transaxles are filled with an inferior fluid, the increased friction and heat can lead to accelerated wear on the gears, bearings, and other internal components. This can result in reduced power, jerky movements, or even complete transaxle failure. The resulting downtime can disrupt the course’s maintenance schedule, leading to dissatisfied golfers and lost revenue. However, by using Hydro-Gear’s genuine commercial transaxle fluid, the golf course can help prevent these issues. The fluid’s superior lubricating properties, heat resistance, and corrosion protection ensure that the transaxles operate smoothly and efficiently, even under heavy use. This translates to improved productivity, reduced maintenance costs, and a longer lifespan for the equipment. The optimized seal compatibility of the fluid also helps to prevent leaks, which can further reduce maintenance costs and environmental impact.

Choosing the Right Transaxle Fluid: OEM vs. Aftermarket Options

When it comes to selecting transaxle fluid for your Hydro-Gear equipped machinery, you’ll encounter two primary options: OEM (Original Equipment Manufacturer) fluids like Hydro-Gear’s genuine product and aftermarket fluids from various brands. While aftermarket fluids may seem tempting due to potentially lower upfront costs, it’s essential to carefully weigh the pros and cons of each option before making a decision. OEM fluids are specifically formulated and tested to meet the exact requirements of the manufacturer’s equipment. In the case of Hydro-Gear, their genuine transaxle fluid is designed to work in perfect harmony with their transaxles, ensuring optimal performance, longevity, and compatibility with seals and other components. This level of tailored performance and compatibility is often difficult to replicate with aftermarket fluids. Aftermarket fluids, on the other hand, are typically designed to be compatible with a wider range of equipment. While this versatility can be appealing, it also means that they may not be optimized for any specific application. The composition and properties of aftermarket fluids can vary widely, and some may not meet the same rigorous standards as OEM fluids. This can lead to reduced performance, increased wear and tear, and even damage to the transaxle. This consideration is especially important when choosing “hydraulic fluid for lawn mower transaxle”.

One of the key advantages of using OEM fluids is the peace of mind that comes with knowing that the fluid has been thoroughly tested and approved by the manufacturer. Hydro-Gear invests significant resources in research and development to ensure that their genuine transaxle fluid meets the highest standards of quality and performance. They conduct extensive testing to evaluate the fluid’s lubricating properties, thermal stability, corrosion protection, and seal compatibility. This rigorous testing process helps to ensure that the fluid will provide optimal protection and performance in their transaxles. Aftermarket fluids may not undergo the same level of testing and quality control, which can increase the risk of problems. While some aftermarket fluids may claim to meet or exceed OEM specifications, it’s important to be cautious and carefully review the product information and specifications. Look for fluids that have been independently tested and certified by reputable organizations. It’s also a good idea to consult with a qualified mechanic or technician to get their recommendation. They can help you assess your specific needs and choose the best fluid for your equipment.

| Factor | OEM Fluid (Hydro-Gear Genuine) | Aftermarket Fluid |

|---|---|---|

| Formulation | Specifically formulated for Hydro-Gear transaxles | Designed for broad compatibility |

| Testing | Extensively tested by Hydro-Gear | Variable testing standards |

| Compatibility | Optimized for Hydro-Gear seals and components | May not be fully compatible |

| Performance | Optimal performance and longevity | Performance may vary |

| Warranty | May be required to maintain warranty | May not affect warranty (check details) |

| Cost | Generally more expensive upfront | Potentially lower upfront cost |

Proper Usage and Maintenance: Maximizing Transaxle Longevity

Even the best transaxle fluid can’t compensate for improper usage or maintenance practices. To maximize the lifespan of your Hydro-Gear transaxle and ensure optimal performance, it’s crucial to follow proper operating procedures and adhere to a regular maintenance schedule. This includes checking the fluid level regularly, changing the fluid at the recommended intervals, and inspecting the transaxle for any signs of leaks or damage. The first step in proper maintenance is to check the fluid level regularly. The frequency of these checks will depend on the equipment’s usage and operating conditions, but it’s generally recommended to check the fluid level at least every 50 hours of operation or once a month, whichever comes first. To check the fluid level, consult the equipment’s owner’s manual for the specific procedure. Typically, this involves removing a dipstick or sight glass and observing the fluid level. If the fluid level is low, add the recommended type of fluid until it reaches the proper level. It’s important to use the correct type of fluid, as using an incompatible fluid can damage the transaxle. The second critical aspect of maintenance is changing the fluid at the recommended intervals. Over time, transaxle fluid can degrade due to heat, oxidation, and contamination. This can reduce its lubricating properties and increase the risk of wear and damage to the transaxle. Therefore, it’s essential to change the fluid at the intervals specified in the equipment’s owner’s manual. The recommended interval will vary depending on the equipment’s usage and operating conditions, but it’s typically between 200 and 500 hours of operation. Also, consider using “hydrostatic drive fluid” for optimal results.

When changing the fluid, it’s important to follow the correct procedure. This typically involves draining the old fluid from the transaxle, replacing the filter (if applicable), and filling the transaxle with fresh fluid. Consult the equipment’s owner’s manual for the specific procedure and recommended fluid type. In addition to checking the fluid level and changing the fluid, it’s also important to inspect the transaxle for any signs of leaks or damage. Leaks can indicate a problem with the seals or other components, while damage can indicate that the transaxle has been subjected to excessive stress. If you notice any leaks or damage, it’s important to have the transaxle inspected and repaired by a qualified mechanic or technician as soon as possible. Ignoring these issues can lead to more serious problems and potentially result in complete transaxle failure. Furthermore, avoid overloading the equipment or operating it in excessively harsh conditions. Overloading the equipment can put excessive stress on the transaxle, leading to premature wear and damage. Operating the equipment in excessively harsh conditions, such as extreme temperatures or dusty environments, can also accelerate the degradation of the fluid and increase the risk of problems. By following these proper usage and maintenance practices, you can significantly extend the lifespan of your Hydro-Gear transaxle and ensure optimal performance. This will translate to reduced maintenance costs, improved reliability, and a longer lifespan for your equipment.

FAQ: Addressing Common Questions About Hydro-Gear Transaxle Fluid

FAQ: Addressing Common Questions About Hydro-Gear Transaxle Fluid

What type of transaxle fluid does my Hydro-Gear unit require?

Determining the correct transaxle fluid for your specific Hydro-Gear unit is crucial for optimal performance and longevity. The best source of information is always your equipment’s owner’s manual. This document will typically specify the exact type of fluid recommended by the manufacturer. If you don’t have access to the manual, you can often find this information on the Hydro-Gear website or by contacting their customer support. Be prepared to provide the model number of your transaxle, which can usually be found on a label or tag attached to the unit. Generally, Hydro-Gear recommends their own genuine commercial transaxle fluid, which is a synthetic or semi-synthetic blend designed to meet the demanding requirements of their systems. However, some older or specialized units may require a different type of fluid. It’s essential to avoid guessing or using a generic fluid, as this can lead to reduced performance, increased wear, or even damage to the transaxle.

How often should I change the transaxle fluid in my Hydro-Gear system?

The frequency of transaxle fluid changes depends on several factors, including the type of equipment, the operating conditions, and the manufacturer’s recommendations. In general, commercial equipment that is used heavily and subjected to harsh conditions will require more frequent fluid changes than equipment used for light-duty applications. The owner’s manual is the best source of information for the recommended fluid change interval. As a general guideline, most Hydro-Gear systems should have their fluid changed every 200 to 500 hours of operation. However, this interval may be shorter if the equipment is used in dusty or wet environments, or if it is subjected to frequent starts and stops. It’s also a good idea to inspect the fluid regularly for signs of contamination or degradation. If the fluid appears milky, foamy, or contains debris, it should be changed immediately, regardless of the recommended interval. Regular fluid changes are essential for maintaining optimal performance and extending the lifespan of the transaxle.

What are the signs that my transaxle fluid needs to be changed?

There are several telltale signs that indicate your transaxle fluid may need to be changed. One of the most obvious signs is a change in the fluid’s appearance. Fresh transaxle fluid is typically clear and bright, with a light amber or red color. As the fluid ages, it can become darker, cloudier, or even black. The presence of debris or sediment in the fluid is another sign that it needs to be changed. This debris can be caused by wear and tear on internal components, or by contamination from external sources. Another sign that your transaxle fluid needs to be changed is a change in the way the equipment operates. This can include reduced power, jerky movements, or unusual noises coming from the transaxle. You might also notice that the transaxle is running hotter than usual. If you experience any of these symptoms, it’s a good idea to check the fluid level and condition. If the fluid is low, dirty, or degraded, it should be changed as soon as possible to prevent further damage to the transaxle. Regular inspections can help you identify these issues early on, preventing larger problems and costly repairs.

Can I use a synthetic blend or full synthetic transaxle fluid in my Hydro-Gear unit?

Yes, using a synthetic blend or full synthetic transaxle fluid in your Hydro-Gear unit is generally acceptable and often recommended. Synthetic fluids offer several advantages over conventional mineral oils, including better thermal stability, improved lubricity, and longer service life. These benefits can translate to improved performance, reduced wear and tear, and a longer lifespan for your transaxle. Hydro-Gear’s genuine commercial transaxle fluid is a synthetic or semi-synthetic blend, indicating that they recognize the benefits of synthetic fluids. However, it’s still essential to consult your equipment’s owner’s manual to ensure that the synthetic fluid you choose meets the manufacturer’s specifications. Pay attention to the viscosity grade, API rating, and any other specific requirements listed in the manual. While synthetic fluids are generally compatible with most seals and components, it’s always a good idea to double-check to avoid any potential issues. Upgrading to a synthetic fluid can be a worthwhile investment, especially for equipment that is used heavily or subjected to demanding operating conditions. Just ensure it meets the specifications.

What happens if I use the wrong type of transaxle fluid in my Hydro-Gear system?

Using the wrong type of transaxle fluid in your Hydro-Gear system can have serious consequences, potentially leading to reduced performance, increased wear, and even damage to the transaxle. Different fluids have different properties, such as viscosity, lubricity, and compatibility with seals and components. Using a fluid that doesn’t meet the manufacturer’s specifications can compromise the transaxle’s ability to function properly. For example, using a fluid with the wrong viscosity can affect the hydraulic pressure within the system, leading to reduced power and jerky movements. Using a fluid that is not compatible with the seals can cause them to swell, shrink, or degrade, resulting in leaks and loss of fluid. And using a fluid that doesn’t provide adequate lubrication can increase friction and wear, leading to premature failure of internal components. In severe cases, using the wrong fluid can cause irreversible damage to the transaxle, requiring costly repairs or even replacement. Always consult the equipment’s owner’s manual to determine the correct type of fluid for your specific Hydro-Gear system.

Where can I purchase genuine Hydro-Gear transaxle fluid?

Genuine Hydro-Gear transaxle fluid can be purchased from several sources, ensuring you have convenient access to the recommended fluid for your equipment. One of the most reliable options is to purchase directly from an authorized Hydro-Gear dealer. These dealers are typically local equipment repair shops, landscaping supply stores, or lawn and garden retailers. They have the expertise to help you choose the correct fluid for your specific Hydro-Gear unit and can also provide maintenance and repair services. Another option is to purchase the fluid online from reputable retailers that specialize in Hydro-Gear parts and accessories. When purchasing online, be sure to verify that the retailer is an authorized dealer to ensure that you are getting genuine Hydro-Gear fluid. You can also check the Hydro-Gear website for a list of authorized online retailers. Avoid purchasing fluid from unverified sources, as there is a risk of getting counterfeit or substandard products. Always check the packaging and labeling to ensure that the fluid is genuine Hydro-Gear and meets the specifications listed in your equipment’s owner’s manual.

Is it difficult to change the transaxle fluid myself, or should I take it to a professional?

The difficulty of changing transaxle fluid yourself depends on your mechanical skills and the specific design of your equipment. For some Hydro-Gear systems, the fluid change process is relatively straightforward and can be accomplished with basic tools and a little bit of mechanical know-how. This typically involves draining the old fluid, replacing the filter (if applicable), and filling the system with new fluid. However, other systems may be more complex and require specialized tools or knowledge. Before attempting to change the fluid yourself, it’s essential to consult the equipment’s owner’s manual for specific instructions and precautions. If you are not comfortable with the process or if you lack the necessary tools or skills, it’s best to take it to a qualified mechanic or technician. They have the expertise and equipment to perform the fluid change correctly and safely. Improperly changing the fluid can damage the transaxle or create a safety hazard. While it may cost more to have a professional change the fluid, it can save you time, effort, and potential headaches in the long run.

Price: $13.49 - $18.99

(as of Sep 06, 2025 10:20:25 UTC – Details)