Carabiner Clip – Heavy Duty Carabiners Review carabiner – Oemiu

Understanding the Basics of Carabiner Clips

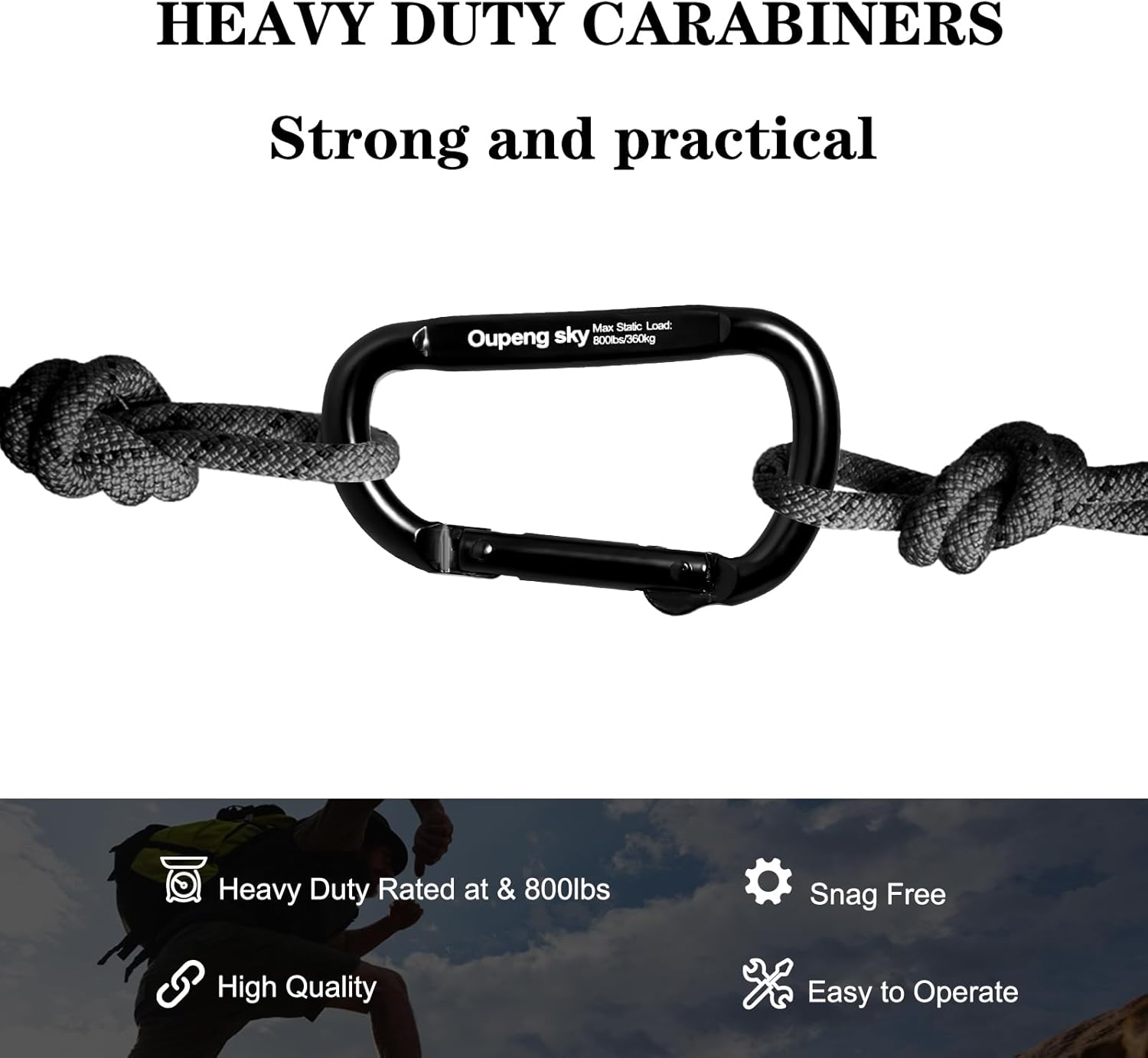

The carabiner clip, a staple in outdoor enthusiasts’ kits, has evolved over the years to become an indispensable tool in various industries, including construction, search and rescue, and even in everyday life. At its core, a carabiner is a metal clip with a spring-loaded gate, used to quickly and securely connect objects. The heavy-duty carabiner, in particular, has gained popularity for its durability and strength, making it a preferred choice for applications where reliability is paramount. These clips come in various shapes, sizes, and materials, each designed to meet specific needs. For instance, aluminum carabiners are lightweight and ideal for climbing, while steel carabiners offer superior strength and are often used in industrial settings.

When it comes to heavy-duty carabiners, the key is in their ability to withstand significant loads without failing. This is crucial in scenarios such as rock climbing, where a carabiner’s failure could have disastrous consequences. Heavy-duty carabiners are designed with safety in mind, featuring robust constructions that can support heavy weights. They are typically made from high-strength materials like stainless steel or durable aluminum alloys. The gate of a heavy-duty carabiner is also designed to be secure, with mechanisms in place to prevent accidental opening, such as screw-lock or auto-locking gates. These features ensure that once a carabiner is clipped onto something, it remains securely in place until intentionally released.

Applications of Heavy-Duty Carabiners

Heavy-duty carabiners have a wide range of applications, reflecting their versatility and reliability. In outdoor adventures, they are used for securing ropes, creating anchors, or even as a part of a pulley system in rescue operations. For example, in search and rescue missions, heavy-duty carabiners are used to lift or lower people or equipment, showcasing their strength and durability in critical situations. In the construction industry, these carabiners are used for lifting heavy materials, offering a secure and efficient way to manage loads on site. Their use extends to sailing and boating, where they are utilized for securing sails or as part of the rigging, demonstrating their adaptability to different environments.

Beyond these industrial and recreational uses, heavy-duty carabiners also find their way into everyday applications. They can be used for securing gear in camping, as a utility clip for hanging tools, or even as a keychain for those who appreciate their durability and functionality. The long-tail carabiner, with its extended clip-in point, is particularly useful for situations where a bit more reach is needed, such as in climbing or when working at heights. Meanwhile, the D-shaped carabiner offers a compact design that distributes the load evenly, making it a favorite among climbers for its strength and minimal weight.

Features and Specifications of Heavy-Duty Carabiners

When selecting a heavy-duty carabiner, several factors come into play, including the material, gate type, weight capacity, and certifications. For instance, a carabiner made from stainless steel will offer excellent resistance to corrosion, making it ideal for use in marine environments or where exposure to the elements is a concern. On the other hand, aluminum carabiners, while lighter, might not offer the same level of strength as their steel counterparts but are preferred for applications where weight is a critical factor.

The gate type of a carabiner is another crucial aspect to consider. Screw-gate carabiners provide a secure closure but can be slower to use, whereas auto-locking gates offer convenience and speed, making them suitable for situations that require quick connections and disconnections. The weight capacity, measured in kilonewtons (kN), is a direct indicator of a carabiner’s strength and should be carefully matched to the intended use to ensure safety.

To compare the features and specifications of different heavy-duty carabiners, consider the following table:

| Carabiner Type | Material | Gate Type | Weight Capacity (kN) | Certifications |

|---|---|---|---|---|

| Steel D-Shaped | Stainless Steel | Screw-Lock | 30kN | EN 362, UIAA |

| Aluminum Oval | Aluminum Alloy | Auto-Lock | 20kN | EN 12275, UIAA |

| Titanium Wire Gate | Titanium | Wire Gate | 25kN | EN 566, UIAA |

Benefits and Considerations of Using Heavy-Duty Carabiners

The benefits of heavy-duty carabiners are numerous, including their reliability, strength, and versatility. They provide a secure way to connect and disconnect objects, which is critical in applications where safety is paramount. The durability of these carabiners means they can withstand harsh environments and heavy use, making them a valuable investment for both professional and recreational use.

However, there are also considerations to keep in mind. The cost of heavy-duty carabiners can be significantly higher than lighter-duty models, which might deter some buyers. Additionally, the weight and size of these carabiners can be a factor in applications where every gram counts, such as in long-distance hiking or climbing. It’s also important to ensure that the carabiner is properly used and maintained to prevent wear and tear, which can compromise its safety and effectiveness.

Some of the key benefits of heavy-duty carabiners include:

- High strength-to-weight ratio

- Durable construction for long lifespan

- Secure gate mechanisms to prevent accidental openings

- Versatility in various applications

- Compliance with international safety standards

On the other hand, some of the considerations are:

- Higher cost compared to lighter-duty models

- Potential for added weight in backpacks or gear

- Need for regular inspection and maintenance

- Importance of selecting the right carabiner for the specific application

Long-Tail Variations of Carabiners

The long-tail carabiner is a variation designed to provide an extended clip-in point, making it easier to connect to anchors or ropes that are slightly out of reach. This feature is particularly beneficial in climbing, where the ability to quickly and safely secure oneself to an anchor point can be crucial. The long-tail carabiner also finds use in search and rescue operations, where the extra length can facilitate the securing of ropes or equipment in complex rescue scenarios.

Other long-tail variations include the micro carabiner, designed for applications where space and weight are critical, such as in camping or hiking. These carabiners offer a compact design without compromising on strength, making them ideal for securing small items like keys, water bottles, or first aid kits. The mini carabiner is another variation, suited for lighter applications such as securing tools or as part of a quick-draw system in climbing.

The main advantage of these long-tail variations is their flexibility and adaptability to different scenarios, from the heavy-duty use in outdoor adventures to the utility use in everyday life. However, the choice of carabiner ultimately depends on the specific requirements of the task at hand, including the weight capacity needed, the environment in which it will be used, and personal preference regarding gate type and material.

Comparing Different Types of Carabiners

Comparing different types of carabiners can be a daunting task, given the variety of materials, designs, and intended uses. However, understanding the key differences can help in selecting the right carabiner for a particular application. For instance, comparing a steel carabiner to an aluminum one involves considering factors such as weight, strength, and durability. Steel carabiners offer superior strength and durability but are heavier, whereas aluminum carabiners are lighter and more corrosion-resistant but might not match the strength of steel.

Another comparison might involve looking at the gate type, where screw-gate carabiners provide maximum security but can be slower to use, and auto-locking gates offer quicker operation but might have a higher risk of accidental opening if not properly closed. The oval carabiner, with its symmetrical design, provides an even distribution of force, making it suitable for applications where the direction of pull is unpredictable.

Ultimately, the choice between different types of carabiners should be based on the specific needs of the task, including the required strength, preferred material, gate type, and any relevant certifications or standards compliance. By carefully considering these factors, one can select a carabiner that not only meets but exceeds the demands of the application, ensuring safety, reliability, and efficiency.

Real-Life Applications and Examples

Heavy-duty carabiners find their way into various real-life applications, showcasing their versatility and reliability. In rock climbing, for example, carabiners are used to connect the rope to anchors, providing a secure point of attachment. The use of carabiners in search and rescue operations is another critical application, where these clips are used to secure ropes, lift equipment, or even evacuated personnel, demonstrating their strength and durability in high-stress situations.

In sailing, heavy-duty carabiners are used to secure sails or as part of the rigging, offering a reliable and efficient way to manage loads on the vessel. The construction industry also relies heavily on these carabiners for lifting heavy materials or securing equipment on site. Even in everyday life, carabiners are used as keychains, utility clips, or

Price: $7.99 - $7.19

(as of Sep 04, 2025 11:35:41 UTC – Details)