Best Art3d Liquid Fusion Activity Play Review math playground Buying Guide

Best Art3d Liquid Fusion Activity Play Review: A Buying Guide for Creative Explorers

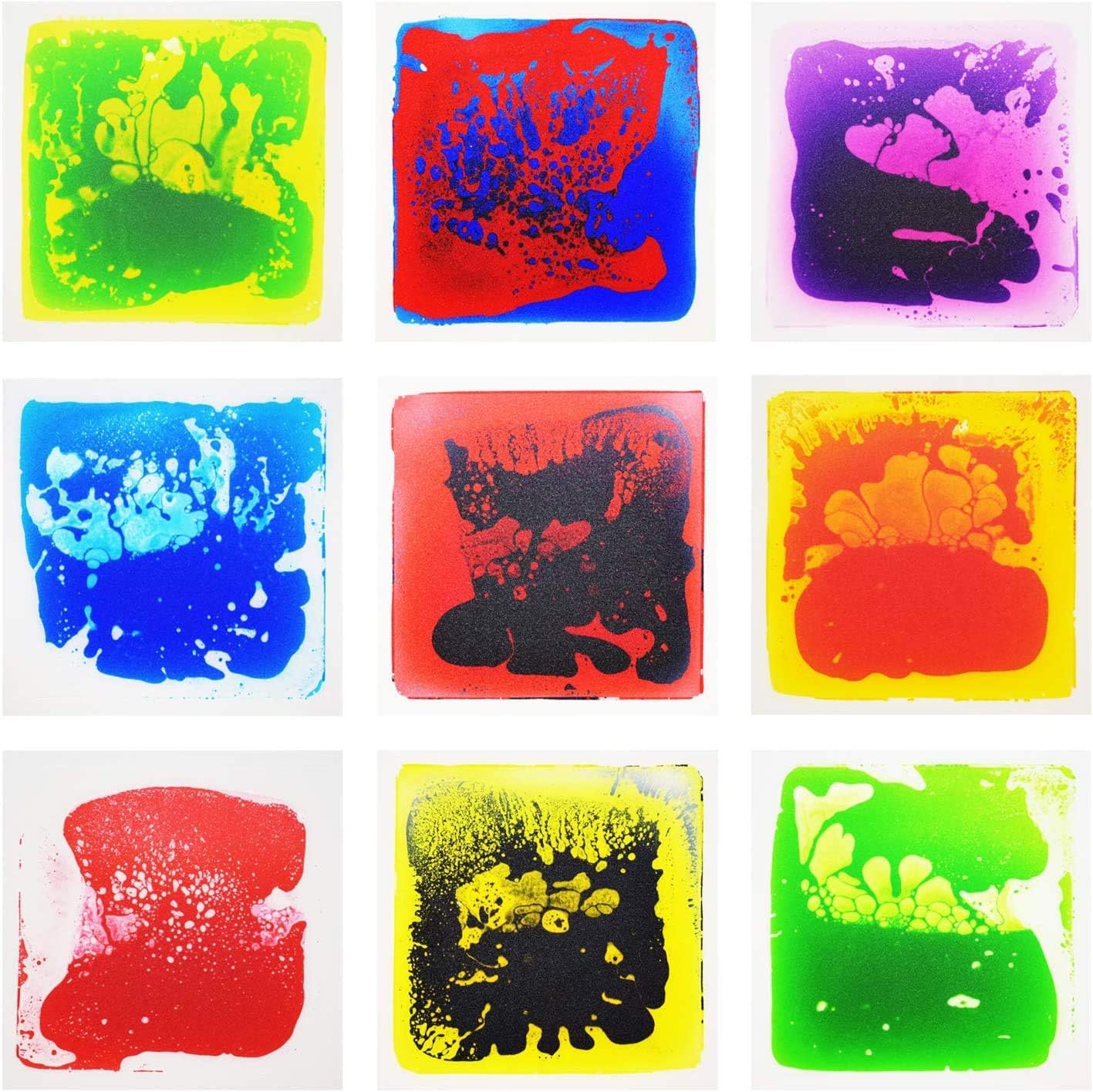

Unleash your inner artist and embark on a captivating journey of creativity with Art3d Liquid Fusion Activity Play. This innovative crafting material offers a world of possibilities, allowing you to create stunning three-dimensional artwork, personalized jewelry, and unique decorative pieces. But with so many options available, selecting the perfect Art3d Liquid Fusion product can feel overwhelming. This comprehensive buying guide will delve into the world of liquid art, exploring its benefits, features, and applications. We’ll navigate the selection process, provide expert tips, and compare different products to help you find the ideal match for your artistic aspirations.

The Allure of Liquid Fusion: Why Choose Art3d?

Art3d Liquid Fusion stands out from traditional crafting materials for its versatility and captivating visual appeal. Unlike rigid mediums, liquid fusion flows and blends seamlessly, allowing for intricate designs and dynamic effects. The translucent quality of the material creates depth and dimension, making your creations truly stand out. Whether you’re a seasoned artist or a beginner exploring your creative side, liquid fusion offers an accessible and rewarding crafting experience. Consider the sheer freedom it allows; you’re not confined to molds or pre-determined shapes. You are essentially painting with light and resin, giving rise to mesmerizing and unique effects every single time. The ability to embed objects, from small beads to dried flowers, adds another layer of personalization to your work. Imagine capturing a specific memory or sentiment within a clear, solidified form. That’s the power of Art3d Liquid Fusion. Furthermore, the durability of the cured resin ensures that your creations are not only beautiful but also long-lasting. They can withstand everyday handling and retain their vibrant colors and clarity for years to come. From delicate jewelry pieces to bold statement art, the possibilities are truly limitless.

One of the key benefits of Art3d Liquid Fusion is its ease of use. Most products come with detailed instructions and require minimal preparation. The two-part resin system typically involves mixing equal parts of resin and hardener, which then cures over a specific period of time. This simple process makes it accessible to crafters of all skill levels. The self-leveling properties of the resin also contribute to the ease of use, ensuring a smooth and even finish. This is particularly helpful for beginners who may struggle with traditional painting or sculpting techniques. With a little practice and experimentation, anyone can create stunning liquid fusion art. For those interested in educational aspects, some might explore online resources like a *math playground* as a way to visualize the mixing ratios and spatial arrangements needed in liquid art projects. In comparison to other art forms, liquid fusion provides a relatively quick and satisfying creative outlet. The curing process typically takes between 24 and 72 hours, depending on the product and environmental conditions. This means you can see the results of your work relatively quickly, which can be highly motivating for beginners. Finally, the clean-up process is relatively straightforward. Most spills and messes can be easily wiped away with a damp cloth or paper towel before the resin cures.

Exploring the Diverse Applications of Art3d Liquid Fusion

The versatility of Art3d Liquid Fusion opens up a vast array of creative possibilities. From crafting personalized jewelry to creating stunning home décor, the applications are limited only by your imagination. Let’s explore some popular uses:

* **Jewelry Making:** Create unique pendants, earrings, and bracelets by embedding beads, glitter, or small objects in the resin.

* **Resin Art:** Pour resin onto canvas or wood panels to create mesmerizing abstract artwork with swirling colors and dynamic effects.

* **Coasters and Trays:** Design functional and beautiful coasters and trays by pouring resin into molds and adding decorative elements.

* **Paperweights and Keepsakes:** Preserve precious memories by embedding photos, dried flowers, or other sentimental items in resin paperweights.

* **Home Décor:** Create unique wall art, table centerpieces, and other decorative accents to personalize your living space.

* **River Tables:** A more advanced technique involves creating stunning “river tables” by pouring resin between pieces of wood to create a translucent river effect.

Beyond these common applications, Art3d Liquid Fusion can also be used for more specialized projects, such as creating custom phone cases, repairing damaged surfaces, and even building small-scale sculptures. The key is to experiment with different techniques and materials to discover new and innovative ways to use this versatile crafting medium. Thinking outside the box is crucial. Perhaps combine liquid fusion with other art mediums like acrylic paint or watercolors for mixed-media effects. Or try using different types of molds to create unique shapes and textures. You could also explore the use of different pigments and dyes to achieve a wide range of colors and effects. Furthermore, liquid fusion is a wonderful art medium to connect to educational concepts; for example, younger users could explore *math playground* resources to understand the geometric principles involved in shaping and pouring the resin to create different forms. The possibilities are truly endless, and the only limit is your own creativity. Remember to always prioritize safety and follow the manufacturer’s instructions when working with resin. Proper ventilation and protective gear are essential to prevent any potential health hazards.

Navigating the Selection Process: Finding the Right Art3d Liquid Fusion for You

With a wide range of Art3d Liquid Fusion products available, choosing the right one for your needs can feel daunting. Consider these factors when making your selection:

* **Viscosity:** The viscosity of the resin refers to its thickness or fluidity. Lower viscosity resins are thinner and easier to pour, making them ideal for intricate designs and embedding small objects. Higher viscosity resins are thicker and more suitable for creating domed or three-dimensional effects.

* **Curing Time:** Curing time refers to the amount of time it takes for the resin to harden and become solid. Faster curing resins are ideal for projects that need to be completed quickly, while slower curing resins allow for more working time and reduce the risk of bubbles.

* **UV Resistance:** UV resistance refers to the resin’s ability to withstand exposure to sunlight without yellowing or fading. If you plan to display your creations in direct sunlight, choose a resin with high UV resistance.

* **Clarity:** The clarity of the resin refers to its transparency. Clear resins are ideal for embedding objects and creating transparent effects, while opaque resins are suitable for creating solid colors.

* **Toxicity:** While most Art3d Liquid Fusion products are non-toxic when cured, it’s important to take precautions when working with uncured resin. Always wear gloves and eye protection, and work in a well-ventilated area.

Consider the specific projects you plan to undertake. If you’re primarily interested in jewelry making, look for a low-viscosity resin with a fast curing time. If you’re planning to create large-scale resin art, choose a high-viscosity resin with good UV resistance. It’s also helpful to read reviews and compare different products to see what other users have to say. Pay attention to the product’s strengths and weaknesses, and consider how they align with your own needs and expectations. Don’t be afraid to experiment with different products to find the one that works best for you. Start with small projects and gradually work your way up to more complex designs. The key is to practice and learn from your mistakes. Another way to approach learning about resin art is to explore related concepts on a *math playground,* which might help understand mixing ratios and surface area principles crucial for successful projects. You can also consult with experienced resin artists for tips and advice. Many online forums and communities are dedicated to resin art, providing a valuable resource for beginners. Remember to always prioritize safety and follow the manufacturer’s instructions when working with resin. With a little research and experimentation, you can find the perfect Art3d Liquid Fusion product to unlock your creative potential.

A Closer Look: Comparing Popular Art3d Liquid Fusion Products

To help you make an informed decision, let’s compare some popular Art3d Liquid Fusion products:

| Product | Viscosity | Curing Time | UV Resistance | Clarity | Price (Approx.) | Pros | Cons |

|---|---|---|---|---|---|---|---|

| Art3d Clear Epoxy Resin Kit | Low | 24-72 hours | Moderate | Excellent | $30 | Easy to use, good clarity, suitable for jewelry making | Moderate UV resistance, can be prone to bubbles |

| Art3d Casting Resin Epoxy Kit | High | 48-72 hours | Good | Good | $40 | Good UV resistance, suitable for large castings, durable | Longer curing time, can be difficult to pour in intricate designs |

| Art3d Epoxy Resin Color Pigment Set | N/A | N/A | N/A | N/A | $20 | Vibrant colors, easy to mix, good value | Can affect the clarity of the resin |

| Art3d Silicone Resin Molds | N/A | N/A | N/A | N/A | $15 | Variety of shapes and sizes, easy to demold | Can be fragile, require proper cleaning |

This table provides a brief overview of some popular Art3d Liquid Fusion products. It’s important to note that prices may vary depending on the retailer and product size. When choosing a product, consider your specific needs and budget. If you’re a beginner, start with a simple kit that includes resin, hardener, and basic tools. As you gain experience, you can experiment with different products and techniques. Don’t be afraid to try new things and push your creative boundaries. You might also find educational value in exploring resources like *math playground fractions* to master the mixing ratios needed for consistent resin results. Remember to always read the product instructions carefully and follow the safety precautions. With a little practice and patience, you can create stunning liquid fusion art that will impress your friends and family.

Essential Tips for Working with Art3d Liquid Fusion: Achieving Professional Results

To ensure successful and professional-looking results, follow these essential tips when working with Art3d Liquid Fusion:

* **Preparation is Key:** Before starting your project, gather all the necessary materials and tools. This includes resin, hardener, molds (if using), pigments, mixing cups, stirring sticks, gloves, eye protection, and a well-ventilated workspace.

* **Precise Mixing Ratios:** Use accurate measuring tools to ensure the correct mixing ratio of resin and hardener. Incorrect ratios can result in sticky or uncured resin.

* **Thorough Mixing:** Mix the resin and hardener thoroughly, scraping the sides and bottom of the mixing cup to ensure complete integration. Avoid whipping or stirring too vigorously, as this can introduce air bubbles.

* **Bubble Removal:** Gently tap the mixing cup on the table to release any trapped air bubbles. You can also use a heat gun or lighter to remove surface bubbles after pouring the resin. Be careful not to overheat the resin, as this can cause it to cure too quickly.

* **Temperature and Humidity:** Maintain a consistent temperature and humidity level in your workspace. Extreme temperatures or humidity can affect the curing process and result in unwanted effects.

* **Dust Control:** Keep your workspace clean and dust-free. Dust particles can settle on the resin surface and affect its clarity.

* **Mold Release:** If using molds, apply a mold release agent to prevent the resin from sticking.

* **Layering:** For layered designs, allow each layer to partially cure before pouring the next layer. This will prevent the colors from mixing and create a more defined effect.

* **Curing Time:** Allow the resin to fully cure according to the manufacturer’s instructions. Avoid touching or disturbing the resin during the curing process.

* **Sanding and Polishing:** After curing, you can sand and polish the resin surface to remove any imperfections and achieve a smooth, glossy finish.

By following these tips, you can minimize the risk of errors and achieve stunning results with Art3d Liquid Fusion. Experiment with different techniques and materials to discover your own unique style. Consider watching online tutorials and joining resin art communities for inspiration and guidance. Remember that practice makes perfect, so don’t be discouraged if your first few projects aren’t perfect. The more you experiment, the better you’ll become. To further enhance your understanding, consider how *math playground games* could be applied conceptually to understand ratios and measurements that are critical for achieving consistent results. And most importantly, have fun and enjoy the creative process! Liquid fusion art is a rewarding and fulfilling hobby that can bring joy and satisfaction to your life.

Frequently Asked Questions (FAQ)

What is Art3d Liquid Fusion and what can I create with it?

Art3d Liquid Fusion is a type of epoxy resin that is specifically designed for crafting and artistic applications. It is a two-part system that consists of a resin and a hardener, which when mixed together, undergo a chemical reaction that causes the mixture to harden into a durable, transparent, and glossy solid. This solidified resin can then be used to create a wide variety of items, from jewelry and coasters to decorative art pieces and even furniture components. The versatility of the material stems from its ability to encapsulate objects, be pigmented to achieve various colors, and be molded into different shapes. Whether you are embedding dried flowers in a pendant, creating a colorful abstract painting on a canvas, or crafting custom-designed coasters, Art3d Liquid Fusion allows you to bring your creative visions to life. The possibilities are truly endless and are limited only by your imagination.

How do I properly mix Art3d Liquid Fusion resin and hardener?

Mixing Art3d Liquid Fusion resin and hardener correctly is crucial for achieving a successful outcome. Always consult the manufacturer’s instructions for the specific product you are using, as the recommended mixing ratios may vary. Typically, you will need to measure equal parts of resin and hardener by volume or weight, using separate measuring cups or syringes to avoid contamination. Pour both components into a clean, dry mixing cup, and then gently stir the mixture with a stirring stick or spatula. Avoid stirring too vigorously, as this can introduce air bubbles. Scrape the sides and bottom of the cup to ensure that all of the resin and hardener are thoroughly combined. The mixture should appear clear and homogenous, without any streaks or swirls. Once mixed, the resin will have a limited working time before it begins to harden, so it is important to proceed with your project promptly. Remember that proper mixing is essential for the resin to cure correctly and achieve its desired properties, such as transparency, hardness, and durability.

What are the best ways to prevent bubbles when working with liquid fusion?

Air bubbles are a common problem when working with liquid fusion, but there are several techniques you can use to minimize their formation and removal. First, stir the resin and hardener gently and avoid whipping the mixture, as this introduces air. Second, warm the resin and hardener slightly before mixing, as this reduces their viscosity and allows bubbles to escape more easily. You can do this by placing the bottles in a warm water bath for a few minutes. Third, pour the resin slowly and carefully to avoid trapping air. Fourth, gently tap the mold or surface after pouring to encourage bubbles to rise to the surface. Finally, use a heat gun or lighter to remove surface bubbles. Hold the heat source a few inches away from the surface and move it quickly back and forth. Be careful not to overheat the resin, as this can cause it to cure too quickly or scorch. Remember, even with these precautions, some bubbles may still form. However, by using these techniques, you can significantly reduce their number and size, resulting in a clearer and more professional-looking finish. It’s also helpful to remember principles learned from a *math playground number line*, visualizing how even slight variations in measurements can impact the final outcome, including bubble formation.

How can I add color to Art3d Liquid Fusion?

There are several ways to add color to Art3d Liquid Fusion, depending on the desired effect and the type of resin you are using. One option is to use resin-specific pigments, which are available in a wide range of colors and forms, including liquid dyes, powders, and pastes. These pigments are specially formulated to mix well with resin without affecting its curing properties or clarity. Another option is to use alcohol inks, which are highly concentrated dyes that create vibrant and translucent effects. A little goes a long way with alcohol inks, so start with a small amount and add more gradually until you achieve the desired color intensity. You can also use acrylic paints, but it is important to use high-quality acrylics that are compatible with resin. Add the paint sparingly to avoid affecting the curing process or clarity of the resin. When adding color, it is important to mix the pigment or dye thoroughly with the resin before pouring. Use a stirring stick or spatula to ensure that the color is evenly distributed throughout the mixture. Remember to test the color on a small sample before pouring it into your final project, as the color may appear different once the resin has cured. Keep in mind that some pigments may affect the UV resistance of the resin, so choose pigments that are specifically designed for resin if you plan to expose your creations to sunlight.

What safety precautions should I take when working with liquid fusion?

Working with Art3d Liquid Fusion involves certain safety precautions that must be followed to protect your health and prevent accidents. Always work in a well-ventilated area to avoid inhaling fumes. Wear gloves to prevent skin contact with the resin and hardener, as they can cause irritation or allergic reactions. Eye protection, such as safety glasses or goggles, is also essential to prevent splashes from getting into your eyes. If you do get resin or hardener on your skin, wash it immediately with soap and water. If it gets into your eyes, flush them with water for at least 15 minutes and seek medical attention. Avoid eating, drinking, or smoking while working with resin. Keep resin and hardener away from children and pets. Follow the manufacturer’s instructions for proper disposal of unused resin and hardener, as they may be considered hazardous waste. Never pour resin or hardener down the drain, as they can clog pipes and contaminate water sources. Store resin and hardener in a cool, dry place, away from direct sunlight and heat. By following these safety precautions, you can minimize the risks associated with working with liquid fusion and ensure a safe and enjoyable crafting experience.

How do I clean up resin spills and messes?

Cleaning up resin spills and messes promptly is important to prevent the resin from hardening and becoming difficult to remove. The best way to clean up uncured resin is to use a solvent such as acetone, isopropyl alcohol, or denatured alcohol. Soak a paper towel or cloth with the solvent and gently wipe away the spilled resin. Repeat as necessary until the surface is clean. Be careful when using solvents, as they are flammable and can irritate the skin and respiratory system. Work in a well-ventilated area and wear gloves and eye protection. If the resin has already started to harden, you may need to scrape it off with a razor blade or putty knife. Be careful not to damage the underlying surface. For hardened resin on tools or mixing cups, soak them in acetone or isopropyl alcohol for several hours or overnight to soften the resin. Then, scrape off the softened resin with a scraper or brush. You can also use a heat gun to soften hardened resin, but be careful not to overheat the resin or the tool. Dispose of used paper towels, cloths, and solvents properly, as they may be considered hazardous waste. Avoid pouring solvents down the drain. By cleaning up resin spills and messes promptly and properly, you can prevent them from becoming a major headache and keep your workspace clean and organized.

How can I achieve a smooth, glossy finish on my liquid fusion creations?

Achieving a smooth, glossy finish on your liquid fusion creations requires careful preparation, proper technique, and attention to detail. First, ensure that the resin is properly mixed and free of bubbles. Second, pour the resin slowly and carefully to avoid creating surface imperfections. Third, use a heat gun or lighter to remove any surface bubbles. Fourth, protect the resin from dust and debris while it is curing. Cover the project with a clean, dust-free container or sheet. Fifth, after the resin has cured, you may need to sand and polish the surface to remove any imperfections. Start with a coarse-grit sandpaper and gradually work your way up to finer grits. Use wet sanding techniques to prevent the sandpaper from clogging and to create a smoother finish. After sanding, use a polishing compound and a soft cloth or polishing wheel to buff the surface to a high gloss. Apply several coats of polish, following the manufacturer’s instructions. Alternatively, you can apply a clear coat of resin to create a smooth, glossy finish. Use a self-leveling resin and pour it evenly over the surface. Remove any bubbles with a heat gun or lighter. By following these steps, you can achieve a professional-looking, smooth, and glossy finish on your liquid fusion creations. Understanding the principles of surface tension and fluid dynamics, perhaps even found through a *math playground simulation*, can aid in achieving this desired finish.

Price: $89.99 - $79.99

(as of Sep 11, 2025 07:10:25 UTC – Details)