6 Inches Wire Cutters with Longer Flush Review wire cutter – Oemiu

The Precision Edge: A Deep Dive into 6-Inch Wire Cutters with Enhanced Flush Cutting Capabilities

For anyone working with electronics, jewelry making, or even some types of craft projects, the right tools are paramount. Among those tools, the humble wire cutter often gets overlooked, yet it plays a critical role in achieving clean, precise results. A quality pair of 6-inch wire cutters with a longer flush cutting surface can dramatically improve the speed and accuracy of your work, reducing frustration and wasted materials. This article explores the nuances of these specialized cutters, highlighting their benefits, key features to look for, and providing insights into choosing the best option for your specific needs.

Understanding the Importance of Flush Cutting and Length

The term “flush cutting” refers to the ability of wire cutters to snip wire as close as possible to a surface, leaving a smooth, even cut with minimal protrusion. This is particularly important in electronics, where protruding wire ends can cause short circuits or snag on other components. Traditional wire cutters often leave a small, sharp point that needs to be filed down or otherwise dealt with, adding extra time and effort to the project. 6-inch wire cutters with longer flush capabilities are designed to minimize this issue, creating a cleaner, more professional finish right from the start.

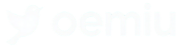

The 6-inch length itself offers a comfortable balance between maneuverability and leverage. Shorter cutters might be easier to fit into tight spaces, but they often lack the leverage needed to cut thicker wires. Longer cutters provide more leverage but can be cumbersome in confined areas. The 6-inch size hits a sweet spot, providing sufficient leverage for most common wire gauges while remaining relatively easy to handle.

Consider, for example, a scenario involving circuit board assembly. When soldering components onto a PCB, the leads often need to be trimmed after soldering. Using standard wire cutters might leave sharp, uneven edges that could potentially damage other components or even injure the user. A 6-inch flush cutter, on the other hand, can trim these leads cleanly and safely, ensuring a professional and reliable connection. Similarly, in jewelry making, flush cutting is essential for creating smooth, snag-free ends on wire components, enhancing the overall quality and comfort of the finished piece. The longer flush cut surface ensures a consistently clean cut across various gauges.

Key Features to Consider When Choosing 6-Inch Wire Cutters

When shopping for 6-inch wire cutters with enhanced flush cutting, several factors should influence your decision. These factors relate to the materials used, the design of the cutting edges, and the overall ergonomics of the tool. Investing in a high-quality pair will save you time, effort, and potential frustration in the long run.

* **Material and Hardness:** The material used for the cutting blades is crucial for their durability and cutting performance. High-carbon steel is a popular choice, known for its strength and ability to hold a sharp edge. Look for cutters with blades that have been hardened and tempered for increased wear resistance. The Rockwell hardness scale (HRC) is often used to measure the hardness of steel; a higher HRC number indicates greater hardness. A good range for wire cutter blades is typically between HRC 55 and HRC 65.

* **Blade Geometry and Precision:** The shape and alignment of the cutting blades are critical for achieving a true flush cut. The blades should meet perfectly along their entire cutting surface, without any gaps or misalignments. Some cutters feature angled blades for improved access in tight spaces. A longer flush cutting surface provides more consistent results across different wire gauges.

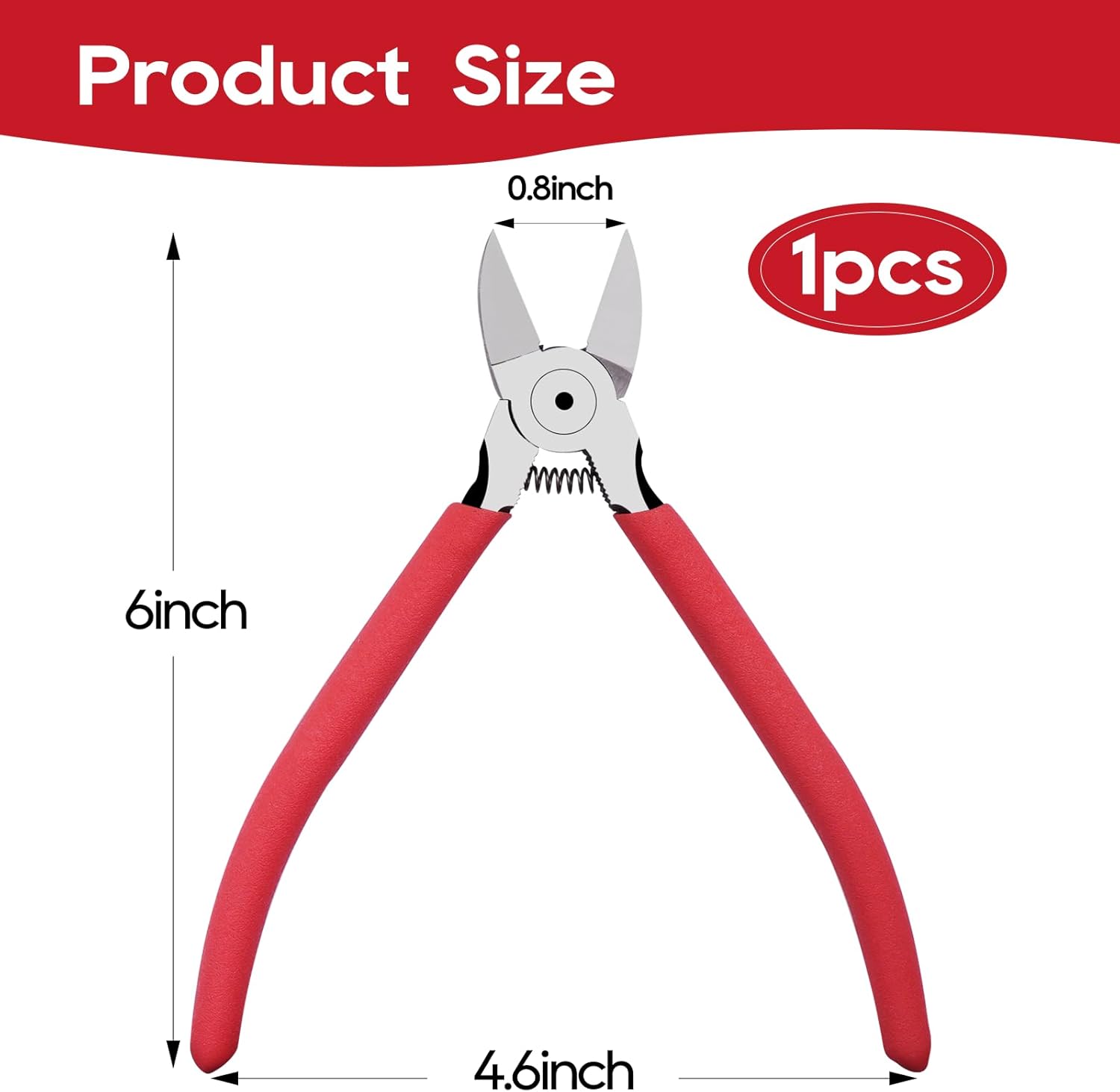

* **Handle Design and Ergonomics:** The handle design significantly impacts comfort and control, especially during prolonged use. Look for handles that are ergonomically shaped and provide a secure grip. Rubberized or cushioned grips can reduce hand fatigue and improve precision. The handle length should be proportionate to the blade size, providing adequate leverage without being unwieldy.

* **Joint Mechanism and Spring Action:** The joint mechanism should be smooth and durable, allowing for effortless opening and closing of the cutters. A spring-loaded mechanism can further reduce fatigue by automatically opening the cutters after each cut. The spring should be strong enough to provide consistent action but not so stiff that it requires excessive force.

* **Cutting Capacity:** Be sure to check the wire gauge and material cutting capacity of the cutters before purchasing. Different cutters are designed for different types and sizes of wire. Trying to cut wire that is too thick or too hard can damage the blades and reduce their lifespan.

Here is a table summarizing the key features to consider:

| Feature | Description | Importance |

|---|---|---|

| Material and Hardness | High-carbon steel, hardened and tempered (HRC 55-65) | Durability, edge retention |

| Blade Geometry and Precision | Perfectly aligned blades, angled blades (optional), longer flush cut surface | Achieving clean, flush cuts |

| Handle Design and Ergonomics | Ergonomic shape, rubberized or cushioned grips | Comfort, control, reduced fatigue |

| Joint Mechanism and Spring Action | Smooth, durable joint, spring-loaded mechanism | Effortless operation, reduced fatigue |

| Cutting Capacity | Wire gauge and material limitations | Preventing damage to blades and ensuring proper cutting performance |

Real-World Applications and Benefits of Using Long Flush Wire Cutters

The benefits of using 6-inch wire cutters with enhanced flush cutting extend beyond simply achieving a cleaner cut. They can also improve efficiency, reduce waste, and enhance safety. Consider the following real-world applications:

* **Electronics Repair and Prototyping:** In electronics repair and prototyping, precision is paramount. Using flush cutters to trim component leads on circuit boards ensures a clean, professional finish and minimizes the risk of short circuits or damage to other components. The longer flush cut capability is particularly useful when working with densely populated boards where space is limited. A high-quality set of electronics wire cutters is essential.

* **Jewelry Making:** Jewelry makers rely on flush cutters to create smooth, snag-free ends on wire components. This is essential for creating comfortable and aesthetically pleasing pieces. The ability to cut wire cleanly and close to the work surface minimizes the need for filing or sanding, saving time and effort.

* **3D Printing Post-Processing:** After printing a 3D object, supports often need to be removed. Flush cutters are ideal for trimming these supports cleanly and precisely, leaving a smooth surface that requires minimal post-processing.

* **Model Building and Hobby Crafts:** Model builders and hobbyists often work with small, delicate parts. Flush cutters allow them to trim these parts cleanly and accurately, without damaging the surrounding material.

* **Floral Arranging:** Surprisingly, long flush wire cutters can be used in floral arranging to cleanly cut stems, avoiding crushing them and allowing for better water absorption, prolonging the life of the arrangement.

The benefits of using these specialized cutters include:

* **Improved Precision:** Flush cutting minimizes the risk of damaging surrounding components or creating sharp edges that could cause injury.

* **Increased Efficiency:** Eliminating the need for secondary finishing processes, such as filing or sanding, saves time and effort.

* **Reduced Waste:** Clean cuts minimize material loss and reduce the risk of damaging workpieces.

* **Enhanced Safety:** By eliminating sharp edges and protruding wire ends, flush cutters reduce the risk of cuts and scrapes.

* **Professional Results:** Clean, precise cuts contribute to a more professional and polished finished product.

Investing in a good pair of 6 inches flush wire cutters is a worthwhile investment for anyone who values precision, efficiency, and safety in their work.

Comparing Different Models of 6-Inch Flush Wire Cutters

The market offers a wide variety of 6-inch wire cutters with enhanced flush cutting capabilities, each with its own strengths and weaknesses. To help you make an informed decision, let’s compare a few popular models based on key features and price. It’s important to find the right wire cutter for electronics and your project needs.

| Model | Material | Handle Material | Cutting Capacity (Wire Gauge) | Features | Approximate Price |

|---|---|---|---|---|---|

| Brand A | High-Carbon Steel (HRC 58) | Ergonomic Rubber Grips | 20 AWG Copper | Spring-loaded, Angled Head | $25 |

| Brand B | Chrome Vanadium Steel (HRC 60) | Cushioned PVC Grips | 18 AWG Copper | Flush Cut, Precision Ground Blades | $35 |

| Brand C | Stainless Steel (HRC 55) | Non-Slip Plastic Grips | 22 AWG Copper | Corrosion Resistant, Fine Wire Cutting | $20 |

| Brand D | High-Carbon Steel (HRC 62) | Comfort Grip Handles | 16 AWG Copper | Longer Flush Cut, Box Joint Construction | $40 |

* **Brand A:** This model offers a good balance of performance and price. The high-carbon steel blades provide decent durability, and the ergonomic rubber grips enhance comfort. The angled head is a useful feature for accessing tight spaces. However, the cutting capacity is limited to 20 AWG copper wire.

* **Brand B:** The chrome vanadium steel blades offer excellent durability and edge retention. The cushioned PVC grips provide comfortable handling, and the precision ground blades ensure a clean, flush cut. The cutting capacity is slightly better than Brand A, at 18 AWG copper wire.

* **Brand C:** This model is a good option for those working in environments where corrosion is a concern. The stainless steel blades are resistant to rust and corrosion. However, the cutting capacity is limited to 22 AWG copper wire, making it unsuitable for thicker wires.

* **Brand D:** This model is the most expensive of the four, but it offers the best overall performance. The high-carbon steel blades are extremely durable, and the comfort grip handles provide excellent control. The longer flush cut and box joint construction ensure precise and reliable cuts. The cutting capacity is also the highest, at 16 AWG copper wire.

Ultimately, the best choice for you will depend on your specific needs and budget. Consider the types of materials you will be cutting, the frequency of use, and the level of precision required. If you primarily work with fine wires in a corrosive environment, Brand C might be the best option. If you need to cut thicker wires and prioritize durability and precision, Brand D would be a better choice. Brand A and Brand B offer good compromises between performance and price for general-purpose use. Remember to consider user reviews as well before deciding on the best precision wire cutter.

Maintenance and Care Tips for Extending the Life of Your Wire Cutters

Proper maintenance and care can significantly extend the lifespan of your 6-inch wire cutters and ensure that they continue to perform optimally. Here are some essential tips:

* **Regular Cleaning:** After each use, wipe the blades clean with a soft cloth to remove any debris, dirt, or residue. This will prevent corrosion and maintain the sharpness of the blades. You can use a mild solvent or cleaner to remove stubborn residue.

* **Lubrication:** Periodically lubricate the joint mechanism with a light oil or lubricant. This will ensure smooth operation and prevent rust. Apply a small amount of lubricant to the joint and work it in by opening and closing the cutters several times.

* **Proper Storage:** Store your wire cutters in a dry, clean place when not in use. Avoid storing them in a tool bag or drawer where they can be exposed to moisture or other corrosive substances. A dedicated tool case or organizer is ideal.

* **Sharpening (If Necessary):** While high-quality wire cutters should hold their edge for a long time, they may eventually become dull with heavy use. If you notice that the cutters are no longer cutting cleanly or require excessive force, consider sharpening the blades. Use a fine honing stone or diamond file to carefully sharpen the cutting edges. Be sure to maintain the original blade angle. If you are not comfortable sharpening the blades yourself, you can take them to a professional sharpening service.

* **Avoid Overloading:** Never attempt to cut wire that is beyond the cutting capacity of your wire cutters. This can damage the blades and reduce their lifespan. Always check the wire gauge and material specifications before cutting.

* **Inspect Regularly:** Regularly inspect your wire cutters for any signs of damage, such as cracks, chips, or loose joints. If you notice any damage, discontinue use and repair or replace the cutters as necessary.

By following these simple maintenance and care tips, you can ensure that your 6-inch wire cutters with longer flush cutting capabilities will provide years of reliable service.

Frequently Asked Questions (FAQ)

What is the difference between flush cut wire cutters and regular wire cutters?

Flush cut wire cutters are designed to cut wire as close as possible to a surface, leaving a smooth, even cut with minimal protrusion. Regular wire cutters, on the other hand, typically leave a small, sharp point or “nip” of wire extending beyond the cut. This difference is primarily due to the blade geometry and precision. Flush cut wire cutters have blades that are ground to a very fine edge and aligned perfectly, allowing them to shear the wire cleanly. Regular wire cutters may have a more rounded or beveled blade, which crushes or deforms the wire during cutting, resulting in the protruding point. The advantage of flush cutting is that it eliminates the need for secondary finishing processes, such as filing or sanding, and reduces the risk of short circuits or injuries from sharp wire ends. They are especially useful when used as jewelry making wire cutters.

What wire gauge should my 6-inch wire cutters be able to handle?

The wire gauge your 6-inch wire cutters should be able to handle depends on the type of work you will be doing. For general-purpose use, a cutting capacity of 18-20 AWG (American Wire Gauge) copper wire is usually sufficient. This will allow you to cut most common types of wires used in electronics, jewelry making, and craft projects. If you frequently work with thicker wires, such as those used in electrical wiring or automotive applications, you may need cutters with a higher cutting capacity, such as 16 AWG or even 14 AWG. Keep in mind that the cutting capacity also depends on the material of the wire. Steel wire, for example, is typically harder to cut than copper wire of the same gauge. Always check the manufacturer’s specifications for the wire cutters to ensure that they are suitable for the types of wires you will be cutting.

How do I sharpen my flush cut wire cutters?

Sharpening flush cut wire cutters requires a delicate touch to maintain the precise blade alignment and cutting edge. Here’s a basic method:

What tools are needed?

You will need a fine honing stone or diamond file, a vise or clamp to secure the cutters, and a magnifying glass to inspect the blades.

Sharpening Steps

1. Secure the cutters in a vise or clamp, ensuring that the blades are accessible.

2. Use the honing stone or diamond file to carefully sharpen the cutting edges. Hold the stone or file at a consistent angle, matching the original blade angle.

3. Work in small, circular motions, applying light pressure. Avoid excessive pressure, as this can damage the blades.

4. Periodically inspect the blades with a magnifying glass to check your progress.

5. Once the blades are sharp, use a soft cloth to remove any metal filings.

6. Lubricate the joint mechanism with a light oil or lubricant.

If you are not comfortable sharpening the blades yourself, it is best to take them to a professional sharpening service.

Are there any safety precautions I should take when using wire cutters?

Yes, safety should always be a priority when using wire cutters. Here are some essential precautions:

* **Wear Safety Glasses:** Always wear safety glasses or goggles to protect your eyes from flying debris. Wire fragments can be ejected with considerable force when cutting, and they can cause serious eye injuries.

* **Use the Correct Tool for the Job:** Use wire cutters that are specifically designed for the type and size of wire you are cutting. Do not attempt to cut wire that is beyond the cutting capacity of the cutters.

* **Maintain a Secure Grip:** Hold the wire cutters firmly and maintain a secure grip. Avoid using excessive force, as this can cause the cutters to slip or break.

* **Cut Away From Your Body:** Always cut away from your body and keep your hands and fingers clear of the cutting area.

* **Inspect for Damage:** Before each use, inspect the wire cutters for any signs of damage, such as cracks, chips, or loose joints. Do not use damaged cutters.

* **Store Properly:** Store wire cutters in a safe place when not in use, away from children and pets.

* **Avoid Cutting Live Wires:** Ensure that the wire you are cutting is not live or energized. Disconnect the power source before cutting any electrical wires.

What are the best brands of 6-inch flush wire cutters?

Several brands are known for producing high-quality 6-inch flush wire cutters. Some popular and reputable brands include:

* **Xuron:** Xuron is a well-regarded brand specializing in precision hand tools, including flush cutters. They are known for their high-quality blades and ergonomic designs, making them a popular choice among electronics enthusiasts and jewelry makers.

* **Hakko:** Hakko is another reputable brand that offers a range of electronics tools, including wire cutters. Their cutters are known for their durability and precision, and they are a popular choice among professionals.

* **Weller:** Weller is a well-known brand in the soldering and electronics industry. They also produce high-quality wire cutters that are designed for precision and durability.

* **Knipex:** Knipex is a German manufacturer known for its high-quality pliers and cutting tools. Their wire cutters are known for their exceptional durability and cutting performance.

* **Lindstrom:** Lindstrom is a high-end brand that produces some of the finest wire cutters available. Their cutters are known for their exceptional precision and sharpness.

How often should I replace my wire cutters?

The lifespan of your wire cutters depends on several factors, including the quality of the cutters, the frequency of use, and the types of materials you are cutting. High-quality wire cutters that are used infrequently and properly maintained can last for many years. However, wire cutters that are used frequently and subjected to heavy use or abuse may need to be replaced more often.

* **Cutting Performance:** If you notice that the cutters are no longer cutting cleanly or require excessive force, it may be time to replace them.

* **Blade Damage:** If the blades are chipped, cracked, or otherwise damaged, they should be replaced.

* **Joint Looseness:** If the joint mechanism becomes loose or wobbly, it can affect the cutting performance and safety of the cutters.

* **Rust or Corrosion:** If the cutters are heavily rusted or corroded, it may be time to replace them.

Can I use 6-inch wire cutters for cutting steel wire?

While some 6-inch wire cutters are capable of cutting steel wire, it is generally not recommended unless the cutters are specifically designed for that purpose. Steel wire is significantly harder and more abrasive than copper or aluminum wire, and cutting it with standard wire cutters can damage the blades and reduce their lifespan. If you need to cut steel wire regularly, you should invest in wire cutters that are specifically designed for cutting hardened materials. These cutters typically have blades made from high-carbon steel or other hardened alloys, and they are designed to withstand the increased wear and tear. Attempting to cut steel wire with standard wire cutters can also be dangerous, as the blades may chip or break, causing injury.

Price: $13.99 - $3.99

(as of Sep 06, 2025 05:36:20 UTC – Details)